How Does a Cold Storage Operate?

Introduction

Cold storage enclosures are essential structures designed specifically for various industrial and commercial applications. These facilities are crucial in numerous industries, particularly those dealing with perishable goods such as food and pharmaceuticals. The primary purpose of cold storage is to provide a controlled environment where temperature-sensitive items can be stored safely and efficiently. PT. BJT INDONESIA, a leading cold storage supplier in India, stands out in this field by offering innovative and efficient prefab cold room solutions that significantly enhance construction efficiency and operational effectiveness. This article will delve into the operation of cold storage facilities, their components, and the various factors that make them indispensable for modern industries.

The Importance of Cold Storage

Preservation of Perishable Goods

The primary function of cold storage is to maintain the quality and extend the shelf life of perishable goods. This includes a wide range of products such as fruits, vegetables, dairy products, meat, seafood, and pharmaceuticals. Without proper temperature control, these items can quickly deteriorate, leading to significant losses for businesses. Cold storage provides the necessary conditions to slow down the metabolic rates of perishables, thus preserving their freshness and nutritional value.

Industrial and Commercial Applications

Cold storage is not limited to the food industry alone. It is also crucial in the pharmaceutical industry for storing vaccines, medicines, and other temperature-sensitive products. Additionally, cold storage facilities are used in the floral industry to keep flowers fresh, in biotechnology for storing biological samples, and even in the film industry for preserving sensitive materials.

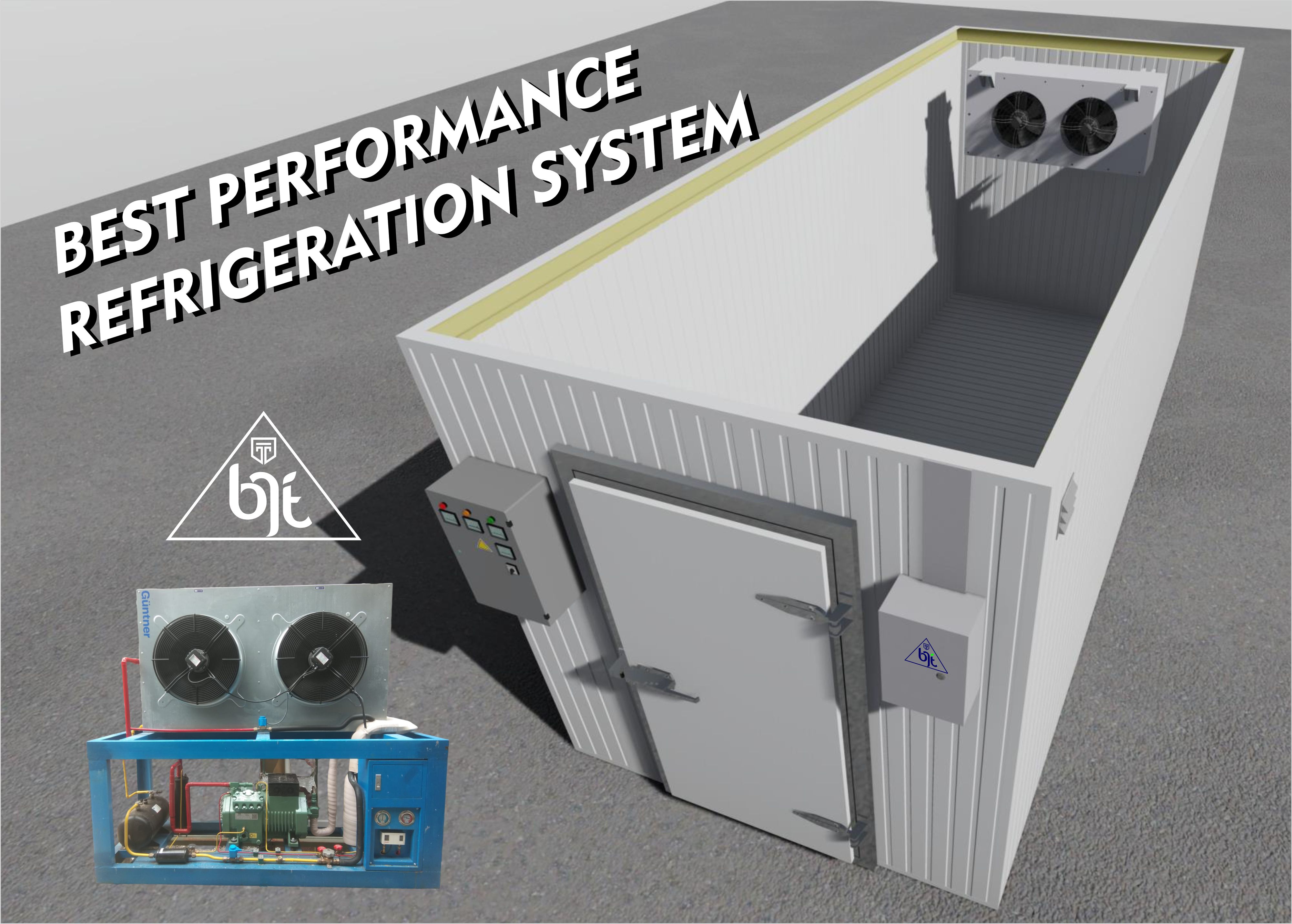

Components of a Cold Storage Facility

Insulated Panels

The core of any cold storage facility is its insulated panels. These panels are designed to provide excellent thermal insulation, preventing the loss of cool air from the storage area. They are typically made from materials with low thermal conductivity, such as polyurethane foam (PUF) or expanded polystyrene (EPS). These panels are not only efficient at maintaining desired temperatures but are also lightweight, making them easy to install and relocate if necessary.

Refrigeration System

The refrigeration system is the heart of a cold storage facility. It comprises compressors, condensers, evaporators, and expansion valves, all working together to remove heat from the storage area and maintain the desired low temperature. The type of refrigeration system used can vary depending on the specific requirements of the facility, including the size of the storage area and the type of goods being stored.

Temperature Control and Monitoring

Accurate temperature control and monitoring are critical for the effective operation of a cold storage facility. Advanced cold storage systems are equipped with digital controls that allow precise temperature settings. Additionally, temperature sensors and monitoring systems continuously track the internal conditions, ensuring that any deviations from the set parameters are immediately addressed. This is particularly important for sensitive products that require strict temperature adherence.

Air Circulation

Proper air circulation is essential in cold storage to ensure uniform cooling throughout the facility. Fans and air distribution systems are used to circulate the cold air, preventing hotspots and ensuring that all stored items receive the same level of cooling. This helps in maintaining consistent product quality and preventing localized spoilage.

Moisture Control

Moisture control is another critical aspect of cold storage operation. Excess moisture can lead to mold growth, product spoilage, and damage to packaging materials. Cold storage facilities are equipped with dehumidifiers and moisture-resistant materials to keep humidity levels in check. This ensures a dry and sterile environment, which is essential for the long-term preservation of goods.

Leakproof Design

A leakproof design is fundamental to maintaining the efficiency and effectiveness of a cold storage facility. Any leakage of cold air can compromise the internal temperature, leading to increased energy consumption and potential spoilage of stored goods. High-quality sealing materials and construction techniques are employed to ensure that the cold storage enclosures are airtight and leakproof.

The Operation Process of Cold Storage

Initial Cooling

When a cold storage facility is first loaded with goods, an initial cooling phase is necessary to bring the temperature down to the desired level. This process can take several hours to days, depending on the volume and type of goods being stored. The refrigeration system works at full capacity during this period to achieve the target temperature.

Steady-State Operation

Once the desired temperature is reached, the cold storage facility enters a steady-state operation phase. The refrigeration system cycles on and off to maintain the set temperature, and the temperature control and monitoring systems ensure that any fluctuations are minimized. During this phase, the energy consumption of the facility is optimized, and the stored goods are kept in ideal conditions.

Loading and Unloading

The process of loading and unloading goods in a cold storage facility must be carefully managed to minimize temperature fluctuations. Rapid door openings can cause warm air to enter the facility, leading to temperature spikes. To mitigate this, cold storage facilities are equipped with rapid-closing doors, air curtains, and vestibules that help maintain the internal temperature during loading and unloading operations.

Regular Maintenance

Regular maintenance of the cold storage facility is crucial for its efficient operation. This includes checking and servicing the refrigeration system, inspecting the insulated panels for any signs of damage, and ensuring that the temperature control and monitoring systems are functioning correctly. Preventive maintenance helps in avoiding unexpected breakdowns and ensures that the facility operates at peak efficiency.

Innovation in Cold Storage Solutions

Prefab Cold Rooms

PT. BJT INDONESIA's prefab cold rooms represent a significant innovation in cold storage solutions. These prefabricated structures are designed for quick and easy installation, making them ideal for businesses that need to set up cold storage facilities rapidly. Prefab cold rooms are built with high-quality insulated panels and come equipped with advanced refrigeration systems, temperature controls, and monitoring devices. Their modular design allows for easy expansion or relocation, providing businesses with the flexibility to adapt to changing storage needs.

Energy Efficiency

Energy efficiency is a key consideration in modern cold storage solutions. With rising energy costs and increasing environmental concerns, cold storage facilities must be designed to minimize energy consumption. This can be achieved through the use of energy-efficient refrigeration systems, advanced insulation materials, and smart control systems that optimize the operation of the facility. PT. BJT INDONESIA's cold storage solutions incorporate these features, helping businesses reduce their energy costs and environmental footprint.

Sustainable Refrigerants

The choice of refrigerant is another important factor in the operation of cold storage facilities. Traditional refrigerants like R404A are being phased out due to their high Global Warming Potential (GWP). In response, the industry is shifting towards more sustainable alternatives such as ammonia (NH3) and carbon dioxide (CO2), which have much lower GWP values. These refrigerants not only reduce the environmental impact of cold storage facilities but also offer improved energy efficiency and performance.

Challenges in Cold Storage Operation

Temperature Fluctuations

One of the primary challenges in cold storage operation is maintaining consistent temperatures. Any fluctuation can compromise the quality of the stored goods. Factors such as frequent door openings, poor insulation, or malfunctioning refrigeration systems can lead to temperature variations. Advanced monitoring and control systems are essential to detect and correct these fluctuations promptly.

Energy Consumption

Cold storage facilities are energy-intensive, and managing energy consumption is a constant challenge. The refrigeration system, which runs continuously to maintain low temperatures, is the main contributor to high energy costs. Implementing energy-efficient technologies and practices, such as using variable speed compressors and high-performance insulation, can help mitigate this issue.

Maintenance and Repairs

Regular maintenance is critical to the smooth operation of cold storage facilities. However, maintenance activities can be disruptive and costly. Finding a balance between routine maintenance and minimizing downtime is essential. Employing skilled technicians and using high-quality components can reduce the frequency and impact of repairs.

Regulatory Compliance

Cold storage facilities must comply with various regulatory standards to ensure the safety and quality of stored goods. These regulations can vary depending on the type of products being stored and the region where the facility is located. Staying up-to-date with regulatory requirements and implementing the necessary measures to comply can be challenging but is crucial for the successful operation of cold storage facilities.

Future Trends in Cold Storage

Automation and IoT

The integration of automation and Internet of Things (IoT) technologies is transforming the cold storage industry. Automated systems can handle tasks such as temperature monitoring, inventory management, and even the loading and unloading of goods. IoT devices provide real-time data on various parameters, enabling predictive maintenance and improved operational efficiency. These technologies help reduce human error, increase precision, and enhance the overall performance of cold storage facilities.

Renewable Energy Integration

As the focus on sustainability grows, integrating renewable energy sources such as solar and wind power into cold storage operations is becoming more common. Renewable energy can significantly reduce the reliance on conventional power sources and lower the overall carbon footprint of the facility. Hybrid systems that combine renewable energy with traditional power sources can ensure a consistent and reliable energy supply.

Advanced Insulation Materials

Research and development in advanced insulation materials are leading to more efficient and effective cold storage solutions. New materials with superior thermal properties can provide better insulation while being lighter and more durable. These advancements contribute to reducing energy consumption and improving the overall efficiency of cold storage facilities.

Modular and Scalable Solutions

The demand for modular and scalable cold storage solutions is on the rise. Businesses need the flexibility to expand or modify their storage facilities as their needs change. Modular cold storage units, like those offered by PT. BJT INDONESIA, allow for easy expansion and reconfiguration without significant disruptions. This adaptability is crucial in meeting the dynamic requirements of modern industries.

Conclusion

Cold storage facilities are vital for the safe and efficient storage of temperature-sensitive goods across various industries. The operation of these facilities involves a combination of advanced technologies, precise temperature control, and regular maintenance to ensure optimal performance. Innovations in prefab cold rooms, energy efficiency, and sustainable refrigerants are driving the industry forward, offering businesses more effective and environmentally friendly solutions. PT. BJT INDONESIA, as a leading cold storage supplier in India, exemplifies these advancements through its innovative and high-quality cold storage solutions. By understanding the operation and benefits of cold storage, businesses can make informed decisions to enhance their storage capabilities, reduce costs, and ensure the optimal preservation of their products. With the rapid advancements in technology, precise temperature control systems have become more accessible and reliable. These systems ensure that perishable goods remain within their required temperature ranges, thereby minimizing spoilage and maximizing shelf life. Moreover, the integration of IoT (Internet of Things) technologies allows for real-time monitoring and remote management of cold storage facilities, enhancing operational efficiency and reducing downtime.

In addition to technological innovations, the emphasis on sustainability is reshaping the cold storage industry. Sustainable refrigerants, such as ammonia and carbon dioxide, are gaining popularity due to their lower environmental impact compared to traditional refrigerants like R404A. These alternatives not only help businesses comply with stringent environmental regulations but also contribute to reducing greenhouse gas emissions and energy consumption. Furthermore, cold storage facilities are increasingly incorporating renewable energy sources such as solar power to further mitigate their carbon footprint and operational costs.

PT. BJT INDONESIA stands out in this evolving landscape as a pioneer in delivering advanced cold storage solutions that prioritize efficiency, reliability, and sustainability. Their commitment to innovation is evident in their prefab cold rooms, which offer modular designs for flexible expansion and relocation options. By choosing PT. BJT INDONESIA’s cold storage solutions, businesses gain access to cutting-edge technologies that ensure the safe storage and preservation of their products while optimizing operational efficiency.

Understanding the operation and benefits of cold storage is crucial for businesses aiming to enhance their storage capabilities and reduce costs. By partnering with a trusted provider like PT. BJT INDONESIA, businesses can leverage state-of-the-art cold storage solutions to meet their specific needs and regulatory requirements. Whether it's maintaining the freshness of perishable goods or optimizing inventory management, investing in advanced cold storage facilities ensures businesses stay competitive in today's dynamic market environment while advancing towards a more sustainable future.