Cold Room Storage Refrigerator Freezer Systems: Comprehensive Guide for Industries

In today's industrial landscape, the demand for cold room storage refrigerators and freezer systems is surging across various sectors. These systems play a critical role in maintaining optimal temperatures for perishable goods, ensuring freshness, quality, and safety. This comprehensive guide explores the applications, benefits, technical specifications, and considerations for implementing cold room storage solutions across diverse industries.

Introduction to Cold Room Storage Systems

Cold room storage systems, also known as walk-in refrigerators and freezers, are specialized environments designed to maintain controlled temperatures essential for preserving perishable items. They are integral to industries such as hospitality, food production, retail, agriculture, pharmaceuticals, and more. These systems offer a versatile solution for storing a wide range of products including fresh produce, dairy, meats, seafood, pharmaceuticals, and chemicals.

Applications of Cold Room Storage Systems

Hospitality Industry

In hotels and resorts, cold room storage systems ensure a continuous supply of fresh ingredients for culinary operations. They help maintain food safety standards and quality, supporting diverse menus and catering services.

Food Production Facilities

Food and beverage factories utilize cold storage systems to store raw materials, intermediate products, and final goods. This ensures product quality, extends shelf life, and minimizes food wastage.

Retail and Supermarkets

Retail outlets and supermarkets rely on cold room storage for displaying and storing perishable goods like dairy products, frozen foods, and fresh produce. These systems enhance product appeal and customer satisfaction by ensuring freshness.

Agriculture and Horticulture

Farms and horticultural facilities use cold storage to preserve harvested crops such as fruits and vegetables. This extends the marketability of produce and minimizes post-harvest losses.

Pharmaceutical and Chemical Industries

In pharmaceuticals, cold room storage systems are critical for storing vaccines, medicines, and biological samples at precise temperatures to maintain efficacy and safety. Similarly, the chemical industry uses these systems for storing sensitive chemicals and compounds.

Logistics and Distribution

Cold storage facilities in logistics and distribution centers facilitate the transportation and storage of temperature-sensitive goods across supply chains. They ensure that products maintain integrity from production to delivery.

Types of Cold Room Storage Systems

Cold room storage systems are categorized based on temperature requirements and applications:

1. Chilled Room

Chilled rooms maintain temperatures typically between 0°C to 8°C. They are ideal for storing fresh produce, dairy products, and beverages that require refrigeration without freezing.

2. Freezer Room

Freezer rooms maintain temperatures below 0°C, typically ranging from -18°C to -25°C or lower. They are designed for storing frozen foods, meats, seafood, and ice cream, preserving them for extended periods.

3. Blast Freezer and Blast Chiller

Blast freezers and blast chillers are specialized units for rapid freezing or chilling of products. Blast freezers quickly freeze products to inhibit bacterial growth and preserve texture and nutrients. Blast chillers rapidly cool cooked foods to safe storage temperatures, maintaining quality and freshness.

Technical Specifications and Features

Cold room storage systems incorporate advanced features to ensure optimal performance and reliability:

-

Temperature Control: Precision temperature control systems maintain consistent temperatures suitable for different types of products.

-

Humidity Control: Adjustable humidity levels prevent moisture buildup, preserving food texture and quality.

-

Insulation: High-quality insulation materials minimize heat transfer and reduce energy consumption.

-

Refrigeration Units: Efficient refrigeration systems ensure rapid cooling or freezing, supported by backup systems for uninterrupted operation.

-

Safety and Monitoring: Integrated alarm systems monitor temperature deviations, power failures, and other critical events to prevent spoilage.

Considerations for Implementing Cold Room Storage Systems

When planning for cold room storage implementation, several factors should be considered:

-

Space Requirements: Calculate the necessary storage capacity based on inventory turnover and product volume.

-

Energy Efficiency: Choose energy-efficient models to reduce operational costs and environmental impact.

-

Compliance and Regulations: Adhere to industry standards and regulations for food safety, pharmaceutical storage, and environmental protection.

-

Maintenance and Support: Implement a proactive maintenance schedule and ensure access to technical support for timely repairs and troubleshooting.

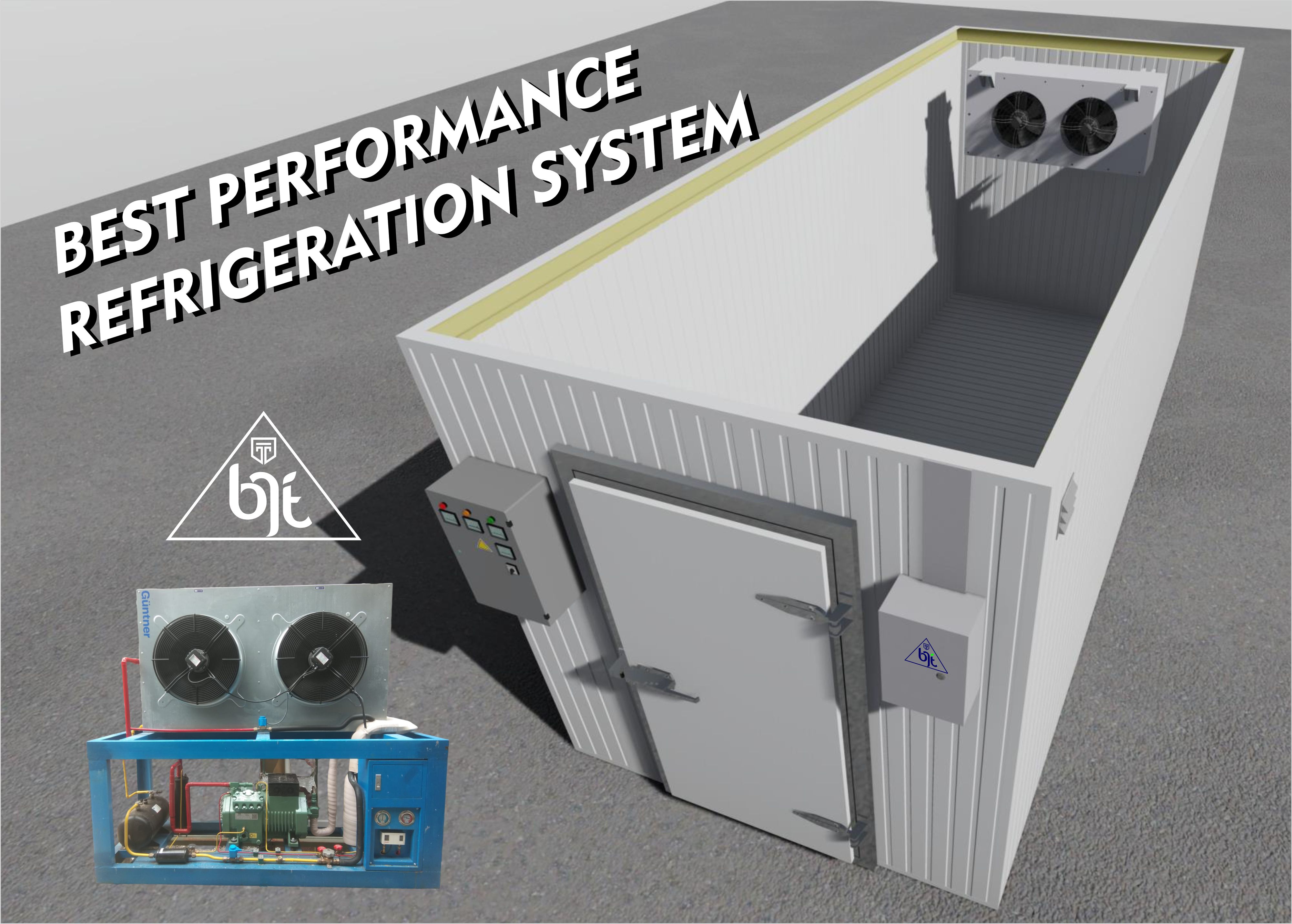

Comprehensive Guide to Cold Storage Construction by PT. BJT INDONESIA

In today's industrial landscape, the necessity for reliable cold storage facilities has become indispensable across various sectors ranging from food and beverage to pharmaceuticals and logistics. PT. BJT INDONESIA, a leading provider of cold storage solutions, emphasizes the importance of competent craftsmanship and extensive experience in constructing cold storage units that meet operational efficiency and user expectations.

Understanding the Cold Storage Construction Process

The construction of a cold storage facility involves meticulous planning and execution to ensure optimal performance and longevity. Here are the key stages involved in the construction process:

1. Needs Analysis

The initial step in constructing a cold storage facility is conducting a comprehensive needs analysis. This involves assessing temperature requirements, storage volume, and the types of products to be stored. Understanding these factors is crucial in determining the appropriate size and capacity of the cold storage unit.

2. Design Planning

Once the temperature and volume requirements are determined, the next step is designing the cold storage facility. This phase considers critical factors such as temperature control, product types, location, and environmental conditions. The design must ensure efficient circulation of cold air and insulation to minimize heat transfer.

3. Fabrication

Fabrication is the stage where the cold storage facility begins to take physical form. It includes constructing the building structure, installing the refrigeration systems, and integrating necessary equipment such as shelving and storage racks. PT. BJT INDONESIA ensures that all fabrication processes adhere to stringent quality standards to guarantee durability and functionality.

4. Installation

Following fabrication, the installation phase involves setting up the refrigeration systems and other essential components of the cold storage unit. This step requires precise execution to ensure that the cooling systems operate effectively and efficiently. Proper installation is critical to preventing temperature fluctuations and maintaining product integrity.

5. Commissioning Test

Commissioning is a crucial step before the cold storage facility can be fully operational. It involves rigorous testing of all systems and equipment to verify their functionality and performance. PT. BJT INDONESIA conducts comprehensive commissioning tests to ensure that the cold storage unit meets safety standards and operational requirements.

Benefits of PT. BJT INDONESIA Cold Storage Solutions

PT. BJT INDONESIA stands out in the market due to its commitment to delivering high-quality cold storage solutions with the following benefits:

-

Quality Assurance: Cold storage units are built to meet stringent quality standards, ensuring reliable performance and longevity.

-

Customization: Tailored solutions to meet specific client requirements regarding size, temperature range, and storage capacity.

-

Efficiency: Utilization of advanced refrigeration technology and energy-efficient designs to minimize operational costs.

-

Durability: Robust construction using high-quality materials that withstands harsh environmental conditions and heavy usage.

-

Compliance: Adherence to industry regulations and standards for food safety, pharmaceutical storage, and environmental sustainability.

Warranty and Support

PT. BJT INDONESIA provides a comprehensive warranty package to ensure customer satisfaction and peace of mind. All cold storage units are covered by a 1-year warranty from the date of installation, guaranteeing the quality and performance of the facility during the critical initial period of operation.

Conclusion

In conclusion, PT. BJT INDONESIA offers reliable cold storage solutions tailored to meet the diverse needs of industries across Indonesia. From initial needs analysis to meticulous design planning, expert fabrication, precise installation, and thorough commissioning, PT. BJT INDONESIA ensures that every cold storage facility delivers optimal performance and meets client expectations. By investing in PT. BJT INDONESIA's cold storage solutions, businesses can enhance their operational efficiency, prolong product shelf life, and maintain superior product quality throughout the supply chai

Conclusion

Cold room storage refrigerators and freezer systems are indispensable assets in modern industries where product integrity and quality are paramount. From enhancing food safety in restaurants to preserving pharmaceuticals and chemicals, these systems support diverse applications across the global supply chain. By understanding their applications, technical specifications, and implementation considerations, businesses can optimize their operations, reduce waste, and meet consumer demands for high-quality, fresh products. Whether for hospitality, food production, retail, or pharmaceuticals, investing in robust cold room storage solutions is essential for maintaining competitiveness and sustainability in today's dynamic market landscape.