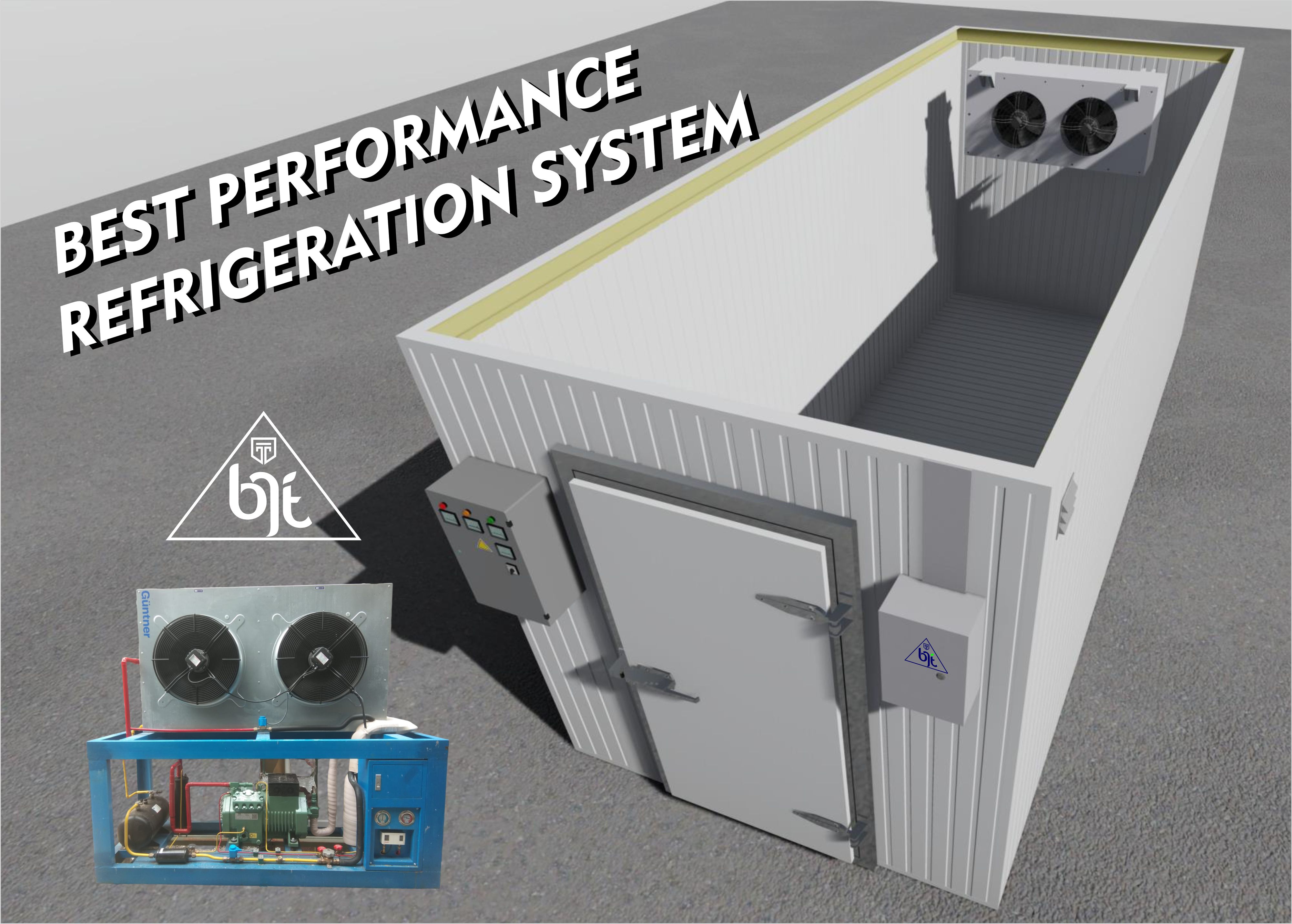

AIR BLAST FREEZER (ABF) ROOM PT. BJT INDONESIA

An Air Blast Freezer (ABF) is a common type of freezing room filled with chilled air. Its advantage lies in utilizing convection currents to efficiently distribute cold temperatures throughout the room. However, the convective heat transfer coefficient of air tends to be small, requiring longer freezing times due to the low rate of heat transfer. The larger the room, the smaller the amount of heat that can be transferred in a given time. Weight loss of products can also occur due to direct contact between the product and water, which can lift the water content in food products, especially if the temperature and humidity allow.

How Air Blast Freezer Works

How Air Blast Freezer Works

The cooling process involves a simple compressor machine that induces condensation, which is then transferred through expansion valves before reaching the evaporator room. The evaporator itself is a part of the cooler that vaporizes food items to low temperatures. Inside, the pressure from the refrigerant will become low pressure so that a high temperature or heat can be released.

This can happen when the refrigerant gas has been sucked by the compressor while the condenser only functions to transfer heat into cold dew, which then becomes liquid refrigerant.

The next task will be carried out by the compressor, which is to lower the temperature to change the form of solid ice. Freezing gas refrigerant or freezing in this way is excellent for preserving food because it will not spoil its taste.

Sandwich Panel Features

Skin Material: Pre-painted galvanized 0.5mm (Food Grade Colorbond by NS-Bluescope)

Skin Color: Rabbit white / Off white

Insulation Material: Polyurethane (PU)

Insulation Density: 40-45 kg/m³

Panel Thickness: 150 mm; 200 mm

Floor System: PU + Concrete; Sandwich Panel; Checkered Aluminum 2mm (Aluminum Bordes)

Door Type: Swing Door / Sliding Door

Knockdown system with easy-to-install cam lock

Heavy-duty Hinge & Handle with safety door lock system

Includes plastic curtain overlapping 20%

Cooling Machine Features

Compressor: Semi Hermetic Two Stage BITZER Germany

Condenser: Guntner / HD / Bitzer Germany (equivalent)

Evaporator: Guntner / Muller (equivalent)

Electric Power: 380 V / 3 Phase / 50 Hz

Temperature: -35°C to -40°C

Sandwich Panel Features

When it comes to constructing a reliable and efficient cold storage facility, the choice of sandwich panel features plays a crucial role in ensuring optimal insulation and durability. Let's delve deeper into each component to understand its significance:

When it comes to constructing a reliable and efficient cold storage facility, the choice of sandwich panel features plays a crucial role in ensuring optimal insulation and durability. Let's delve deeper into each component to understand its significance:

Skin Material: The skin material of the sandwich panel is crafted from pre-painted galvanized steel, with a thickness of 0.5mm. This high-quality material is specifically designed for food-grade applications and is sourced from NS-Bluescope, a renowned provider of premium steel products. The pre-painted surface offers enhanced corrosion resistance and aesthetics, while the galvanized steel base provides structural integrity and longevity.

Skin Color: The skin of the sandwich panel is available in two color options: Rabbit white and Off white. These neutral hues not only complement various architectural styles but also contribute to a clean and professional appearance.

Insulation Material: The core insulation material of the sandwich panel is made of polyurethane (PU), a highly effective thermal insulator known for its low thermal conductivity and excellent moisture resistance. With an insulation density ranging from 40 to 45 kg/m³, the PU foam ensures superior thermal performance, minimizing heat transfer and maintaining stable temperature conditions within the cold storage facility.

Panel Thickness: The sandwich panel is available in two thickness options: 150mm and 200mm. The choice of panel thickness depends on the specific requirements of the cold storage application, with thicker panels offering enhanced insulation properties and structural stability.

Floor System: The floor system of the cold storage facility can be customized to suit different preferences and operational needs. Options include a PU foam + concrete combination, sandwich panel flooring, or a checkered aluminum (2mm) surface (Aluminum Bordes). Each flooring option offers unique benefits in terms of durability, hygiene, and ease of maintenance.

Door Type: The cold storage facility can be equipped with either swing doors or sliding doors, depending on space constraints and user preferences. Swing doors provide easy access and are ideal for smaller spaces, while sliding doors offer efficient utilization of space and smooth operation in larger installations.

Knockdown System: The sandwich panel features a knockdown system with easy-to-install cam locks, allowing for quick and hassle-free assembly and disassembly. This modular design facilitates flexible configuration and adaptation to changing storage requirements, making it an ideal choice for dynamic environments.

Heavy-Duty Hinge & Handle: The door hinges and handles are engineered for heavy-duty use, ensuring long-lasting performance and reliability. The safety door lock system enhances security and prevents unauthorized access, safeguarding valuable inventory and maintaining product integrity.

Plastic Curtain: The sandwich panel includes a plastic curtain with a 20% overlapping design, providing additional insulation and preventing heat infiltration. This feature helps optimize energy efficiency and temperature control within the cold storage facility, contributing to operational cost savings and environmental sustainability.

Compressor: The cold storage facility is equipped with a semi-hermetic two-stage compressor manufactured by BITZER Germany, renowned for its reliability, efficiency, and durability. The compressor ensures consistent cooling performance and precise temperature control, essential for preserving perishable goods.

Condenser: The condenser unit, supplied by reputable brands such as Guntner, HD, or equivalent BITZER Germany models, efficiently dissipates heat from the refrigerant, maintaining optimal operating conditions for the cooling system.

Condenser: The condenser unit, supplied by reputable brands such as Guntner, HD, or equivalent BITZER Germany models, efficiently dissipates heat from the refrigerant, maintaining optimal operating conditions for the cooling system.

Evaporator: The evaporator, provided by trusted manufacturers such as Guntner or Muller, facilitates the evaporation of refrigerant, effectively cooling the air within the cold storage facility. Its high-quality construction ensures efficient heat exchange and uniform temperature distribution.

Electric Power: The cooling system operates on 380 V electrical power, compatible with 3-phase supply at a frequency of 50 Hz. This standard electrical configuration ensures reliable performance and compatibility with existing power infrastructure.

Temperature Range: The cold storage facility offers a temperature range from -35°C to -40°C, suitable for preserving a wide range of perishable goods, including frozen foods, pharmaceuticals, and biological samples. The precise temperature control enables compliance with industry regulations and ensures product quality and safety.

Air Blast Freezer (ABF) Room PT. BJT INDONESIA: Enhancing Industrial Refrigeration Solutions

Introduction to Air Blast Freezer Rooms

In the realm of industrial refrigeration, where the preservation and quality of perishable goods are paramount, Air Blast Freezer (ABF) rooms play a pivotal role. These specialized cold storage solutions are designed to rapidly and efficiently freeze large quantities of products, catering to industries such as food processing, fisheries, pharmaceuticals, and beyond. PT. BJT INDONESIA, a leading provider of industrial refrigeration solutions, offers state-of-the-art ABF rooms tailored to meet the stringent demands of modern businesses.

Understanding Air Blast Freezing Technology

Air Blast Freezers operate on the principle of forced air circulation combined with rapid cooling mechanisms. Unlike conventional freezers, which rely on static air and slower cooling rates, ABF rooms utilize powerful fans to circulate chilled air evenly throughout the storage space. This accelerated airflow ensures uniform temperature distribution, allowing products to reach their desired frozen state quickly and efficiently.

Applications and Industries Served

-

Food Processing: ABF rooms are indispensable in food processing facilities for freezing raw materials, semi-processed foods, and finished products like frozen meals and desserts. They help maintain food quality, extend shelf life, and meet stringent hygiene and safety standards.

-

Fisheries and Seafood: The fisheries industry relies heavily on ABF rooms to freeze freshly caught fish, seafood, and marine products rapidly. This preserves the freshness and nutritional value of seafood, ensuring it reaches global markets in optimal condition.

-

Pharmaceuticals: In pharmaceutical manufacturing, ABF rooms are utilized to freeze temperature-sensitive drugs, vaccines, and biological products. Precise temperature control and rapid freezing capabilities are crucial to maintaining the efficacy and integrity of pharmaceutical products.

-

Export and Logistics: ABF rooms facilitate the export of perishable goods by ensuring products are frozen quickly and uniformly. This is particularly important for exporting fruits, vegetables, meats, and other temperature-sensitive products to international markets.

Design and Construction Features

PT. BJT INDONESIA's ABF rooms are engineered with advanced features to optimize performance, energy efficiency, and durability:

-

Insulation: Utilizes high-density Polyurethane (PU) panels with thicknesses tailored to specific temperature requirements (-40°C and below). This insulation minimizes heat transfer and enhances energy efficiency.

-

Air Circulation: Equipped with high-performance fans and air distribution systems to ensure consistent airflow and temperature uniformity throughout the chamber. This prevents cold spots and ensures even freezing of products.

-

Refrigeration System: Includes high-capacity compressors, efficient condensers, and state-of-the-art refrigerant systems (e.g., R404A) chosen for their cooling efficiency, reliability, and environmental sustainability.

-

Control Systems: Integrated with advanced temperature and humidity control systems, often featuring digital controllers with precise setpoint management, alarms for temperature deviations, and data logging capabilities.

-

Construction Materials: Built with robust materials such as pre-painted galvanized iron for external cladding, stainless steel frames for structural integrity, and durable flooring options suitable for heavy-duty use.

Operational Efficiency and Benefits

-

Rapid Freezing: Capable of reducing temperatures from ambient to -40°C within a specified time frame, ensuring products are quickly frozen to preserve quality and freshness.

-

Energy Efficiency: Designed with energy-efficient components and insulation materials to minimize operational costs while maximizing cooling performance.

-

Hygiene and Safety: Complies with international standards for hygiene and safety, featuring easy-to-clean surfaces, seamless construction, and optional hygiene accessories to prevent contamination.

-

Customization: Tailored to meet specific customer requirements, including chamber size, temperature range, shelving configurations, and additional features like access doors, ramps, and emergency alarms.

Case Studies and Success Stories

PT. BJT INDONESIA has successfully implemented ABF rooms for a diverse range of clients, enhancing their operational capabilities and product quality. Case studies highlight the versatility and reliability of ABF rooms in various industries, showcasing their impact on reducing waste, improving logistics, and expanding market reach.

Conclusion

In conclusion, PT. BJT INDONESIA's Air Blast Freezer (ABF) rooms represent a pinnacle of technological advancement in industrial refrigeration. Designed to meet the rigorous demands of modern businesses across food processing, fisheries, pharmaceuticals, and beyond, these rooms ensure efficient and reliable freezing of perishable goods. With a commitment to quality, innovation, and customer satisfaction, PT. BJT INDONESIA continues to lead in providing cutting-edge ABF room solutions that drive business growth and sustainability in the global market.

For businesses looking to enhance their cold storage capabilities with advanced ABF technology, PT. BJT INDONESIA stands ready to deliver tailored solutions that meet the highest standards of performance, efficiency, and reliability. Contact PT. BJT INDONESIA today to explore how ABF rooms can optimize your cold storage operations and elevate your competitive edge in the industry.

For more information, visit www.bjtindonesia.id.