Refrigerated Storage Solutions

1. Refrigeration Systems:

Refrigeration systems are the heart of any refrigerated storage solution, responsible for maintaining the desired temperature inside cold storage facilities. There are several types of refrigeration systems, each with its own characteristics and applications.

Compression Refrigeration: Compression refrigeration is the most widely used type of refrigeration system. It operates on the principles of compression and expansion of refrigerant gases to remove heat from the storage area. Here's a more detailed breakdown of its components and operation:

-

Compressor: The compressor plays a central role in the system. It pressurizes and circulates the refrigerant gas through the entire cycle. As the gas is compressed, its temperature and pressure increase.

-

Condenser: The high-pressure, high-temperature refrigerant gas then passes through a condenser. In the condenser, the gas releases heat to the surrounding environment and transforms into a high-pressure liquid.

-

Expansion Valve: After leaving the condenser, the high-pressure liquid refrigerant passes through an expansion valve. This valve reduces the pressure and temperature of the refrigerant, causing it to expand into a low-pressure gas.

-

Evaporator: The low-pressure gas enters the evaporator, which is located inside the cold storage area. As the refrigerant evaporates, it absorbs heat from the surroundings, thus cooling the storage space.

This cycle of compression, condensation, expansion, and evaporation continues, maintaining the desired temperature inside the storage facility. The efficiency and performance of compression refrigeration systems depend on factors like the type of refrigerant used and the design of the equipment.

Absorption Refrigeration: Absorption refrigeration systems differ from compression systems in that they use a heat source, such as natural gas or waste heat, to drive the refrigeration process. These systems are often found in industrial applications and can provide cooling without relying on electricity. Here's a closer look at how absorption refrigeration works:

-

Generator: In absorption refrigeration, a generator uses a heat source to boil a refrigerant solution (commonly water and ammonia). This produces vaporized ammonia gas.

-

Condenser: The vaporized ammonia gas is then condensed into a high-pressure liquid in the condenser. This release of heat helps to maintain the desired temperature in the storage area.

-

Evaporator: The high-pressure liquid ammonia passes through an expansion valve, reducing its pressure and temperature, allowing it to evaporate in the evaporator. This process absorbs heat from the storage space, thereby cooling it.

-

Absorber: After evaporating in the evaporator, the low-pressure ammonia gas is absorbed into a solution in the absorber. This solution is then pumped back into the generator to restart the cycle.

Absorption refrigeration systems are known for their ability to utilize waste heat and their relatively quiet operation. They are commonly used in applications where electricity may be limited or costly.

2. Cold Storage Facilities:

Cold storage facilities are essential components of the refrigerated storage industry, providing controlled environments for the safe storage of temperature-sensitive products. These facilities come in various forms, each tailored to specific requirements:

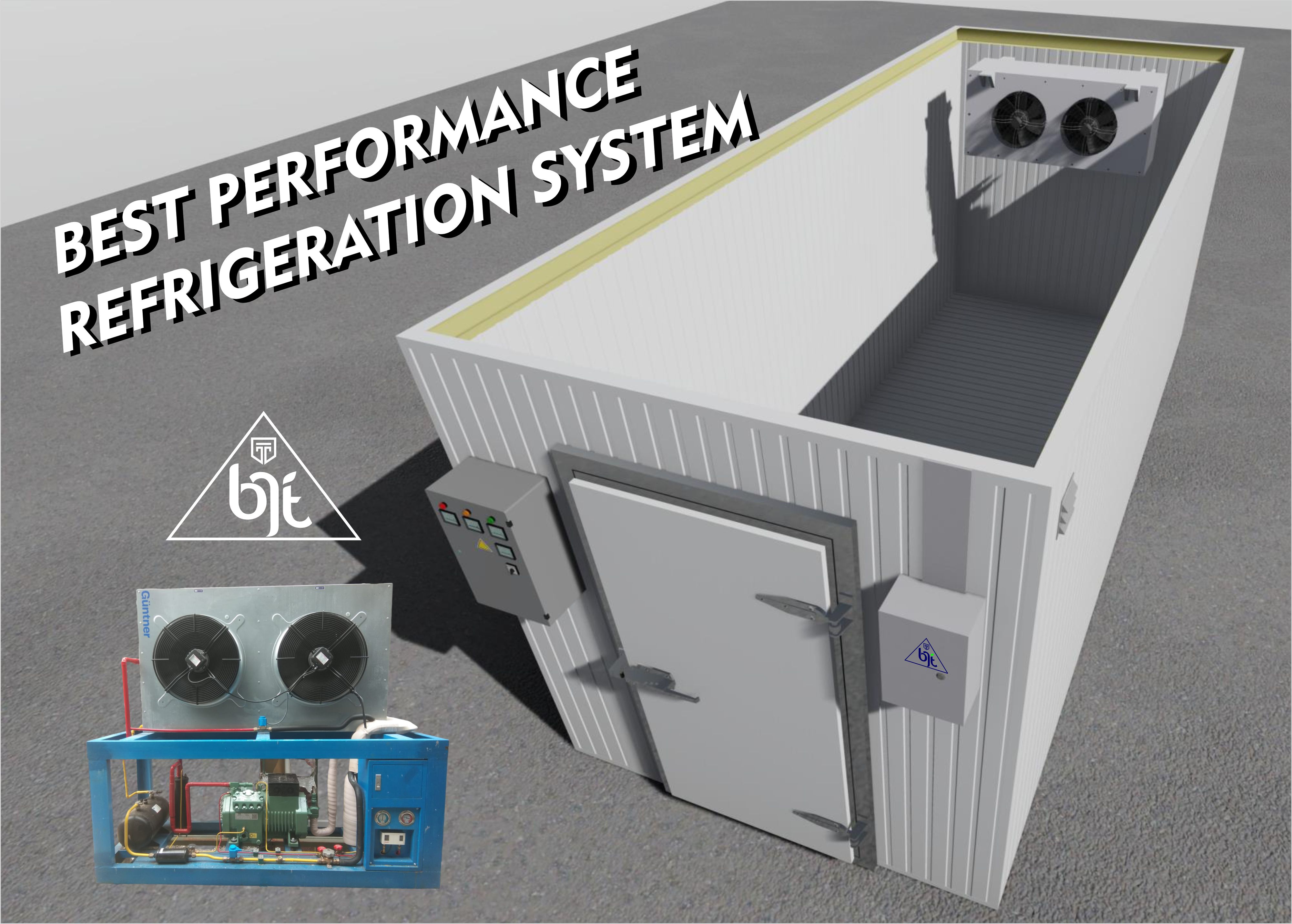

Cold Rooms: Cold rooms are versatile, insulated spaces designed to maintain specific temperature and humidity levels. They are used across industries, including food storage, pharmaceuticals, and research. Cold rooms can be customized to accommodate various temperature ranges, making them suitable for storing everything from fresh produce to vaccines.

Cold rooms typically consist of insulated walls, floors, and ceilings, equipped with refrigeration systems and airflow controls. The insulation ensures minimal heat transfer between the interior and exterior, while the refrigeration system maintains the desired temperature. Advanced cold rooms may incorporate automated monitoring and control systems to optimize temperature and humidity conditions.

Freezers: Freezers are specialized cold storage units designed to maintain temperatures well below freezing, typically at -20°C (-4°F) or lower. These units are essential for the long-term storage of frozen foods, ice cream, and certain pharmaceuticals.

Freezers are equipped with powerful refrigeration systems, extra-thick insulation, and tight sealing mechanisms to prevent frost build-up and maintain low temperatures. Some freezers also include blast freezing capabilities to rapidly freeze products, preserving their quality by minimizing ice crystal formation.

Walk-in Coolers: Walk-in coolers are smaller-scale refrigerated storage units designed for easy access and storage of perishable items. They are commonly used in restaurants, convenience stores, and foodservice establishments. Walk-in coolers provide a controlled environment to keep products fresh and extend their shelf life.

These units are available in various sizes and configurations, accommodating different storage needs. Walk-in coolers are equipped with refrigeration systems, shelving, and lighting for convenience and accessibility.

3. Refrigerated Trucks and Containers:

Refrigerated trucks and containers are crucial for transporting temperature-sensitive goods over various distances while maintaining their cold chain integrity. They are vital links in the distribution of perishable products, ensuring that they reach their destination in optimal condition.

Refrigerated Trucks: Refrigerated trucks, also known as "reefer trucks," are specially designed vehicles equipped with integrated refrigeration units. These trucks are commonly used in the food and beverage industry to transport fresh and frozen products from manufacturers or distribution centers to retailers or end customers.

Refrigerated trucks come in various sizes, ranging from small vans to large tractor-trailers. The refrigeration units are capable of maintaining specific temperature ranges, making them suitable for transporting a wide range of products, including fruits, vegetables, dairy, and frozen meats.

Refrigerated Containers: Refrigerated shipping containers, often referred to as "reefer containers," serve a similar purpose to refrigerated trucks but are designed for intermodal transport. They are typically used for long-distance shipping of temperature-sensitive goods by sea, rail, or truck.

These containers are equipped with their own refrigeration systems and are designed to maintain consistent temperatures, even in challenging environmental conditions. They are essential for global trade, enabling the transport of goods across continents while preserving their quality.

Refrigerated containers are available in various sizes, including 20-foot and 40-foot containers, and can be adapted to meet specific temperature requirements.

4. Refrigeration Monitoring and Control Systems:

Effective monitoring and control systems are essential to ensure the proper functioning of refrigerated storage solutions. These systems help maintain the desired temperature and humidity levels, prevent temperature fluctuations, and provide real-time alerts in case of deviations. Key components of monitoring and control systems include:

Temperature Sensors: Temperature sensors are strategically placed throughout the storage area to continuously monitor temperature conditions. These sensors can detect even minor fluctuations and transmit data to a central control unit.

Humidity Sensors: In certain applications, such as storing fresh produce or pharmaceuticals, humidity levels are critical. Humidity sensors measure moisture levels and help maintain the desired relative humidity within the storage space.

Control Panels: Control panels house the interface through which operators can set and adjust temperature and humidity settings. Advanced control panels may offer remote access and the ability to create temperature profiles for specific products.

Alarms and Alerts: Refrigeration monitoring systems are equipped with alarms and alert mechanisms. When temperature or humidity conditions deviate from the set parameters, the system triggers alarms, notifying operators or maintenance personnel. These alerts help prevent product spoilage and maintain the integrity of the cold chain.

Data Logging and Analysis: Many monitoring systems include data logging capabilities, allowing for the recording and analysis of temperature and humidity data over time. This historical data can be valuable for compliance reporting and quality assurance.

Remote Monitoring: In today's connected world, remote monitoring capabilities are increasingly common. Operators can access real-time data and control settings from smartphones or computers, providing greater flexibility and responsiveness to potential issues.

Energy Management: Some advanced systems incorporate energy management features to optimize energy consumption and reduce operating costs while still ensuring temperature stability.

Compliance and Reporting: For industries with strict regulatory requirements, monitoring systems often include features for generating compliance reports. These reports demonstrate adherence to temperature and humidity standards, which is crucial for food safety and pharmaceutical quality control.

Backup Systems: To ensure continuous operation, backup power and cooling systems may be integrated into monitoring and control systems. These systems can be vital in preventing temperature excursions during power outages.

The implementation of robust monitoring and control systems is essential for meeting regulatory requirements, maintaining product quality, and preventing costly spoilage incidents in refrigerated storage facilities.

5. Refrigerated Shelving and Racking:

Proper shelving and racking systems play a critical role in optimizing storage capacity and airflow within cold storage facilities. These systems are designed to maximize space utilization while ensuring that products remain accessible and are stored in a way that maintains temperature integrity.

Key Features and Considerations:

-

Material Selection: Shelving and racking materials must be compatible with cold storage environments. Materials that resist corrosion, moisture, and temperature extremes are essential to ensure long-term durability.

-

Adjustability: Many systems offer adjustable shelving heights and configurations to accommodate varying product sizes and packaging.

-

Airflow Design: Proper airflow is crucial for maintaining uniform temperatures throughout the storage area. Shelving and racking systems should allow air to circulate freely, preventing temperature stratification and ensuring consistent conditions.

-

Density: High-density storage systems, such as mobile racking, maximize storage capacity within limited space while still allowing easy access to stored items.

-

Hygiene and Cleaning: In environments like food storage, it's important that shelving and racking systems are easy to clean and maintain to meet hygiene standards.

-

Accessibility: Efficient shelving and racking systems should allow for easy access to products. This is particularly important in high-throughput operations, where quick retrieval is essential.

-

Safety: Safety features, such as load-bearing capacities and anti-tip mechanisms, are critical to prevent accidents and protect both personnel and stored goods.

-

Customization: Shelving and racking systems can often be customized to fit the specific layout and needs of the cold storage facility, maximizing storage efficiency.

Properly designed shelving and racking systems not only help optimize space but also contribute to the overall functionality and efficiency of refrigerated storage facilities.

6. Refrigerated Display Cases:

Refrigerated display cases are a common sight in supermarkets, convenience stores, and foodservice establishments. These cases are designed to showcase perishable goods, such as meats, dairy products, and fresh produce, while maintaining the proper temperature and humidity levels to preserve product quality.

Types of Refrigerated Display Cases:

-

Open Display Cases: These cases are open at the front, allowing customers to easily access and select products. They are often used for items like deli meats, cheeses, and bakery goods.

-

Closed Display Cases: Closed cases have glass doors that provide a clear view of the products while keeping them protected from contaminants and maintaining a stable temperature. They are commonly used for dairy products, frozen foods, and beverages.

-

Refrigerated Islands: These are large, open cases with multiple sections that can hold a variety of products. They are often used for displaying fresh produce, meats, and other perishables.

-

Bakery Display Cases: These cases are specially designed for showcasing baked goods while maintaining the ideal temperature and humidity to keep them fresh.

-

Deli Display Cases: Deli cases are designed to display sliced meats, cheeses, and prepared foods. They often have curved glass fronts for an attractive presentation.

Key Features and Considerations:

-

Temperature Control: Display cases are equipped with refrigeration systems that maintain precise temperature settings, ensuring that products are kept at the correct storage temperature.

-

Humidity Control: Some display cases include humidity controls to maintain the freshness of products that are sensitive to moisture levels, such as fruits and vegetables.

-

LED Lighting: Energy-efficient LED lighting is commonly used in display cases to illuminate products and enhance their presentation.

-

Adjustable Shelving: Display cases often feature adjustable shelving to accommodate products of various sizes and shapes.

-

Energy Efficiency: Many modern display cases are designed to be energy-efficient, with features like automatic door closers and improved insulation to reduce energy consumption.

-

Remote Monitoring: Like other refrigeration systems, display cases can be equipped with remote monitoring and control capabilities to ensure consistent performance and provide alerts in case of temperature deviations.

Refrigerated display cases are not only functional but also serve as important marketing tools, allowing retailers to showcase their products and attract customers with appealing presentations of fresh and perishable items.

7. Blast Chillers and Freezers:

Blast chillers and freezers are specialized appliances used in commercial kitchens, food production facilities, and restaurants to rapidly lower the temperature of hot or cooked food items. These appliances play a crucial role in food safety and quality by quickly reducing the core temperature of food, preventing bacterial growth, and preserving flavor and texture.

Key Features and Benefits:

-

Rapid Cooling: Blast chillers and freezers are designed to cool food quickly, reducing its temperature from a high cooking temperature to a safe storage temperature in a short amount of time. This rapid cooling prevents the "danger zone" (40°F to 140°F or 4°C to 60°C), where bacteria multiply most rapidly.

-

Preservation of Quality: By rapidly cooling food, blast chillers and freezers help preserve the quality, flavor, and texture of dishes. This is especially important for high-end restaurants and catering services that need to maintain consistent food quality.

-

Safety Compliance: Blast chilling and freezing are essential for complying with food safety regulations. They ensure that food is stored at safe temperatures, reducing the risk of foodborne illnesses.

-

Extended Shelf Life: Properly cooled and stored food has an extended shelf life, reducing food waste and saving costs for businesses.

-

Versatility: These appliances are versatile and can handle a wide range of food items, from soups and sauces to large cuts of meat and baked goods.

-

Energy Efficiency: Modern blast chillers and freezers often come equipped with energy-efficient features, such as adjustable cooling cycles and improved insulation, to reduce energy consumption.

Blast chillers and freezers are indispensable in commercial kitchens, helping chefs and foodservice professionals maintain food safety standards, streamline food preparation processes, and deliver high-quality meals to customers.

8. Refrigerated Warehousing:

Refrigerated warehousing plays a crucial role in the storage and distribution of temperature-sensitive goods in bulk quantities. These large-scale facilities are commonly used by food distributors and manufacturers to store products before they are shipped to retailers or consumers.

Key Features and Considerations:

-

Temperature Zones: Refrigerated warehouses are often divided into multiple temperature zones to accommodate a variety of products. These zones can range from -30°C (-22°F) for deep frozen products to 15°C (59°F) for products that require cooler storage.

-

Racking Systems: To maximize storage capacity, refrigerated warehouses use high-density racking systems. These systems are designed to store products efficiently while ensuring proper airflow and access.

-

Inventory Management: Advanced inventory management systems are crucial for tracking product quantities, expiration dates, and order fulfillment. These systems help minimize waste and ensure that products are rotated to maintain freshness.

-

Cross-Docking: Some refrigerated warehouses offer cross-docking services, where products are transferred directly from incoming shipments to outgoing trucks, reducing storage time and ensuring timely deliveries.

-

Energy Efficiency: Refrigerated warehouses are under increasing pressure to reduce energy consumption. This includes using LED lighting, high-efficiency refrigeration systems, and energy management systems to optimize operations.

-

Security and Access Control: Security measures are essential in refrigerated warehousing to protect valuable and perishable goods. Access control systems and surveillance cameras help ensure the security of the facility.

Refrigerated warehousing is a critical link in the cold chain, allowing products to be stored in bulk quantities for extended periods while maintaining their quality and safety.

9. Modular and Portable Refrigeration:

Modular and portable refrigeration solutions are designed to provide flexibility for businesses with temporary or changing storage needs. These solutions are ideal for various scenarios, including seasonal demand fluctuations, temporary storage requirements, and disaster relief efforts.

Types of Modular and Portable Refrigeration:

-

Portable Cold Storage Units: These are standalone refrigerated containers or trailers that can be easily transported to a location and set up as needed. They are often used for short-term storage during events, outdoor catering, or emergencies.

-

Modular Cold Rooms: Modular cold rooms are pre-fabricated and designed for easy assembly and disassembly. They can be customized in terms of size, temperature range, and features, making them suitable for a wide range of applications.

-

Temporary Refrigerated Buildings: These are larger, temporary structures that can be set up on-site to provide additional refrigerated storage space during peak seasons or special events.

Advantages of Modular and Portable Refrigeration:

-

Flexibility: Businesses can scale their refrigerated storage capacity up or down as needed, without the need for permanent installations.

-

Mobility: Portable units can be moved to different locations, making them suitable for catering businesses, events, and disaster response.

-

Customization: Modular solutions can be tailored to specific temperature and storage requirements, ensuring that products are kept at the desired conditions.

-

Cost-Efficiency: These solutions can be more cost-effective than constructing permanent cold storage facilities, especially for businesses with changing storage needs.

Modular and portable refrigeration solutions offer businesses the adaptability they need to meet fluctuating demands while ensuring that products remain stored at the appropriate temperatures.

10. Energy-Efficiency Solutions:

Energy efficiency is a growing concern in the refrigerated storage industry due to both environmental and economic factors. Energy-efficient solutions are designed to reduce energy consumption while still maintaining the required temperature conditions. Here are some key strategies and technologies for achieving energy efficiency:

Variable-Speed Compressors: Variable-speed compressors can adjust their speed based on cooling demand, reducing energy consumption during periods of lower demand.

LED Lighting: Replacing traditional lighting with energy-efficient LED lighting can significantly reduce energy usage in cold storage facilities.

Improved Insulation: Upgrading insulation materials and sealing gaps and cracks in the building envelope can enhance temperature stability and reduce the load on refrigeration systems.

Energy Management Systems: These systems use advanced algorithms to optimize the operation of refrigeration equipment, reducing energy usage while maintaining temperature stability.

Heat Recovery: Heat recovery systems capture waste heat generated during the refrigeration process and repurpose it for other heating needs within the facility, such as space heating or water heating.

Advanced Refrigerants: The choice of refrigerant can also impact energy efficiency. Some newer refrigerants have lower global warming potential (GWP) and improved energy efficiency.

Regular Maintenance: Proper maintenance of refrigeration equipment is essential for optimizing energy efficiency. Regularly cleaning coils, checking for refrigerant leaks, and ensuring all components are working efficiently can make a significant difference in energy usage.

Energy-efficient refrigerated storage solutions not only reduce operating costs but also contribute to sustainability goals by lowering greenhouse gas emissions associated with energy consumption.

11. Cold Chain Management Software:

Cold chain management software is a critical component of refrigerated storage solutions, especially in industries where maintaining the integrity of the cold chain is paramount. This software provides real-time visibility into the movement of temperature-sensitive products throughout the supply chain. Key features and functions of cold chain management software include:

Temperature Monitoring: The software continuously monitors temperature conditions at various points along the supply chain, from production facilities to distribution centers and retail stores.

Data Logging: Temperature data is logged and stored for compliance and quality control purposes. This historical data can be used for regulatory reporting and analysis.

Alerts and Notifications: The software can send alerts and notifications in real-time or via email/SMS when temperature deviations occur. This allows for immediate corrective action to prevent product spoilage.

Tracking and Tracing: Cold chain management software enables tracking and tracing of products, allowing businesses to quickly identify the source of any temperature issues or quality concerns.

Compliance Reporting: The software generates compliance reports that demonstrate adherence to temperature requirements and regulations, which is essential for audits and regulatory inspections.

Integration: Many cold chain management systems can integrate with other supply chain management software and hardware, such as RFID and barcode scanners, to provide a comprehensive view of product movement.

Predictive Analytics: Some advanced systems use predictive analytics to anticipate temperature fluctuations and optimize temperature control, helping prevent issues before they occur.

Cloud-Based Solutions: Cloud-based cold chain management software allows for easy access to data and real-time monitoring from anywhere with an internet connection.

Cold chain management software is particularly critical in industries like pharmaceuticals and food, where maintaining the temperature integrity of products is essential for safety and quality.

12. Alternative Refrigerants:

The choice of refrigerants used in refrigerated storage solutions has a significant impact on both environmental sustainability and compliance with evolving regulations. Traditional hydrofluorocarbon (HFC) refrigerants, while effective at cooling, are associated with high global warming potential (GWP) and contribute to climate change. As a result, there is a growing interest in alternative refrigerants with lower GWP and reduced environmental impact. Here are some common alternative refrigerants:

Hydrofluoroolefins (HFOs): HFO refrigerants have gained popularity as alternatives to HFCs. They have significantly lower GWP values and are considered more environmentally friendly. HFOs are used in a range of refrigeration applications, including cold storage facilities and refrigerated transport.

Natural Refrigerants: Natural refrigerants, such as carbon dioxide (CO2 or R-744), ammonia (NH3 or R-717), and hydrocarbons (e.g., propane and isobutane), are gaining traction due to their minimal environmental impact. Each natural refrigerant has its own set of applications, with CO2 often used in supermarket refrigeration systems, ammonia in industrial refrigeration, and hydrocarbons in small commercial refrigeration units.

Blends and Mixtures: Some refrigerants are formulated as blends or mixtures, combining different components to achieve specific performance characteristics. These blends are designed to provide a balance between cooling efficiency and environmental impact.

Regulatory Compliance: As regulatory bodies worldwide implement stricter regulations to reduce greenhouse gas emissions, businesses using refrigerated storage solutions are encouraged to transition to alternative refrigerants with lower GWP values to comply with these regulations.

Safety Considerations: It's important to note that while alternative refrigerants offer environmental benefits, they may also present safety considerations. Businesses must follow safety protocols and standards when using alternative refrigerants, as they may have different flammability or toxicity profiles compared to traditional refrigerants.

In conclusion, refrigerated storage solutions encompass a wide range of components and technologies that are vital for preserving perishable goods, maintaining product quality, and ensuring food safety. From the choice of refrigeration system to the use of alternative refrigerants and advanced monitoring software, each element plays a crucial role in the efficient operation of cold storage facilities and the broader cold chain. As industries continue to evolve and adapt to changing regulations and sustainability goals, the development and implementation of innovative refrigerated storage solutions will remain a key focus for businesses worldwide.