Keunggulan Layanan Gudang Berpendingin

Layanan gudang berpendingin adalah solusi yang sangat penting dalam industri pengelolaan logistik dan stok yang memerlukan suhu terkontrol. Mereka memungkinkan perusahaan untuk menjaga keunggulan dalam pengiriman dan penyimpanan barang dengan suhu yang tepat.

Pengendalian Suhu yang Tepat

Salah satu keunggulan utama dari layanan gudang berpendingin adalah pengendalian suhu yang tepat. Dalam lingkungan ini, suhu dijaga dengan presisi untuk memastikan produk tetap dalam kondisi optimal. Misalnya, makanan beku, produk farmasi, dan bahan kimia sensitif memerlukan suhu yang tepat agar tidak rusak.

Pengawasan Keamanan

Gudang berpendingin juga dilengkapi dengan pengawasan keamanan yang ketat. Ini mencakup pengawasan CCTV, sistem keamanan, dan akses terbatas. Dengan demikian, produk dalam gudang berpendingin aman dari risiko pencurian dan kerusakan.

Keandalan dalam Pengiriman

Layanan gudang berpendingin tidak hanya tentang penyimpanan tetapi juga pengiriman. Mereka memastikan barang sampai pada tujuan dengan keadaan yang baik. Ini sangat penting dalam distribusi makanan beku, produk medis, dan barang berharga lainnya.

Efisiensi Energi

Layanan gudang berpendingin yang modern juga dirancang dengan efisiensi energi. Mereka menggunakan teknologi canggih untuk meminimalkan konsumsi energi, menjaga suhu tetap stabil, dan mengurangi dampak lingkungan. Ini adalah contoh konkret dari bagaimana teknologi dapat membantu mencapai keunggulan yang berkelanjutan.

Memenuhi Standar Kualitas

Dalam dunia yang penuh dengan regulasi dan standar kualitas, layanan gudang berpendingin telah terbukti memenuhi persyaratan ini. Mereka sering mengikuti pedoman ketat dalam pengelolaan barang yang memerlukan suhu terkontrol. Hal ini menjadikan mereka pilihan terbaik untuk bisnis yang peduli akan kualitas dan keamanan produk mereka.

Kesimpulan

Layanan gudang berpendingin adalah elemen kunci dalam rantai pasokan produk yang memerlukan suhu terkontrol. Mereka menghadirkan keunggulan dengan mengendalikan suhu dengan presisi, mengawasi keamanan, dan memenuhi standar kualitas. Mereka juga membantu dalam pengiriman yang handal dan efisiensi energi. Dengan demikian, mereka tidak hanya menjaga produk tetap dingin, tetapi juga membuka jalan menuju keunggulan dalam industri yang sangat kompetitif.

Di balik kulit industri makanan yang berkilauan dan pasokan obat-obatan yang andal, ada infrastruktur yang kurang terlihat namun sangat penting: gudang berpendingin. Gudang ini, seringkali dikenal sebagai cold storage, adalah pusat operasi yang menjaga kualitas dan kesegaran produk yang memerlukan suhu terkendali. Mari kita selami dunia "gudang berpendingin" ini dan lihat bagaimana layanan gudang berpendingin dapat membuka pintu keunggulan di balik pintu berpendingin.

Kunci Kesuksesan dalam Penyimpanan Dingin

Gudang berpendingin adalah tulang punggung dalam industri makanan, farmasi, dan sektor lain yang bergantung pada suhu terkendali. Di dalamnya, daging, ikan, buah-buahan, sayuran, obat-obatan, dan vaksin dijaga agar tetap segar dan aman. Mengingat perlindungan kualitas produk adalah tujuan utama, gudang berpendingin harus memiliki teknologi yang canggih, serta tim yang berpengalaman dalam pemeliharaan dan manajemen operasi.

Layanan Gudang Berpendingin: Membuka Keunggulan

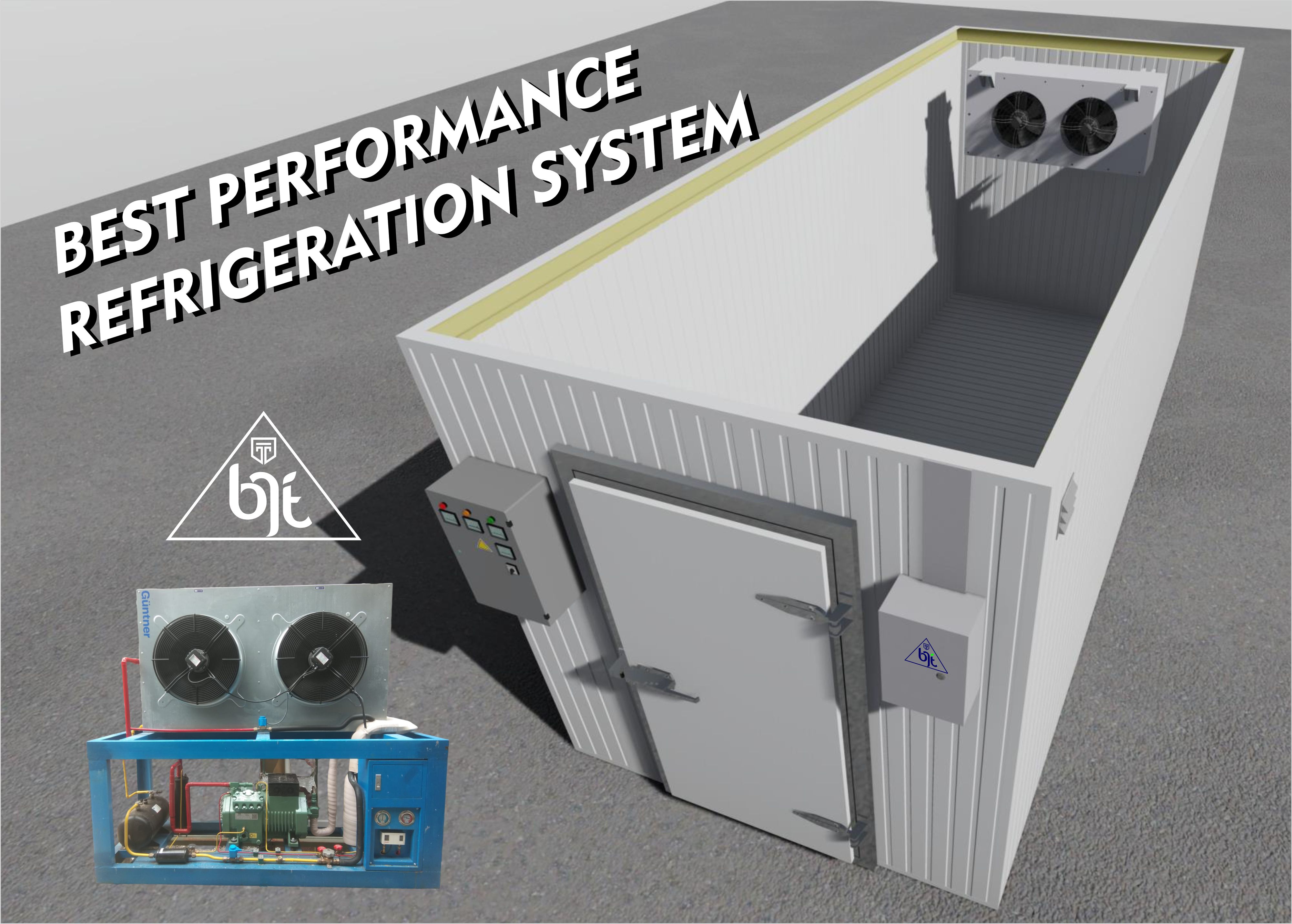

Jika ada yang mengetahui betapa pentingnya layanan gudang berpendingin, itu adalah PT. Bangkit Jaya Teknik Indonesia. Mereka memahami bahwa keandalan gudang berpendingin adalah kunci sukses bagi bisnis yang bergantung pada penyimpanan produk dengan suhu terkendali. Oleh karena itu, mereka menawarkan layanan perawatan dan layanan gudang berpendingin yang unggul. Ini adalah kunci untuk membuka keunggulan.

Dalam dunia bisnis yang kompetitif, di mana setiap detik sangat berharga, keandalan operasi gudang berpendingin adalah segalanya. Gudang yang efisien dan andal memastikan produk-produk tersebut tetap dalam kondisi terbaik. Kelembaban dan suhu tetap dalam kendali, menjaga kesegaran produk, dan membantu memenuhi berbagai regulasi yang ketat dalam industri makanan dan farmasi.

Teknologi Canggih dalam Perawatan

Gudang berpendingin tidak hanya soal suhu rendah; itu juga berkaitan dengan presisi. PT. Bangkit Jaya Teknik Indonesia memahami bahwa peralatan dan teknologi canggih diperlukan untuk menjaga gudang berpendingin dalam kondisi optimal. Mereka memiliki tim teknisi yang berpengalaman yang melakukan perawatan rutin dan pemeriksaan yang sangat teliti.

Perawatan ini mencakup pemeriksaan kompresor, kondensor, evaporator, dan komponen penting lainnya dalam sistem pendingin. Ini adalah langkah kunci dalam memastikan gudang berpendingin tetap beroperasi dalam performa optimal. Selain itu, pemantauan suhu yang ketat juga dilakukan untuk memastikan bahwa suhu tetap sesuai dengan standar yang ditetapkan.

Mendukung Industri Farmasi

Industri farmasi adalah salah satu sektor yang sangat mengandalkan gudang berpendingin. Dalam dunia yang terus berubah dengan perkembangan obat-obatan dan vaksin, gudang berpendingin adalah bagian yang tak terpisahkan. Produk farmasi yang sensitif terhadap perubahan suhu harus disimpan dalam kondisi ideal untuk memastikan keamanan dan efektivitas.

Layanan gudang berpendingin PT. Bangkit Jaya Teknik Indonesia mencakup pengelolaan persediaan obat-obatan dan vaksin. Mereka juga memberikan saran untuk meningkatkan efisiensi energi, yang pada akhirnya dapat membantu menghemat biaya operasional jangka panjang. Ini adalah dukungan berharga bagi perusahaan farmasi yang berjuang untuk memenuhi permintaan pasokan obat-obatan yang berkualitas.

Pelatihan Personel dan Keberlanjutan

Terakhir, pelatihan personel adalah elemen penting dalam menjaga gudang berpendingin beroperasi dengan efisien. Personel yang terlatih dengan baik dapat mengidentifikasi masalah potensial dan mengambil tindakan yang tepat dalam situasi darurat. Ini adalah langkah penting dalam menjaga operasi berjalan lancar.

Dalam upaya mendukung keberlanjutan, PT. Bangkit Jaya Teknik Indonesia juga mempertimbangkan strategi penghematan energi dalam gudang berpendingin. Ini adalah langkah penting dalam mengurangi dampak lingkungan dan menghemat biaya operasional dalam jangka panjang.

Kesimpulan

Gudang berpendingin mungkin tidak selalu terlihat, tetapi peran mereka sangat vital dalam menjaga kualitas produk dan operasi bisnis yang sukses. PT. Bangkit Jaya Teknik Indonesia memahami pentingnya layanan gudang berpendingin yang andal dan efisien. Layanan mereka membantu membuka pintu keunggulan, menjaga produk segar, dan mendukung bisnis dalam berbagai sektor, termasuk makanan dan farmasi. Dalam dunia yang terus berkembang, gudang berpendingin adalah mitra tak tergantikan dalam menjaga kualitas produk dan keberlanjutan.

Chilling Precision: Unlocking Excellence with Refrigerated Warehouse Services

In the heart of industries reliant on temperature-sensitive goods, the role of refrigerated warehouse services takes center stage. Amidst the ebb and flow of commerce, PT. Bangkit Jaya Teknik Indonesia emerges as a masterful conductor, orchestrating a symphony of preservation within their state-of-the-art refrigerated warehouses. These facilities aren't just storage spaces; they are fortresses of freshness, sanctuaries of safety, and embodiments of uncompromising quality.

Picture a labyrinth where each corner houses a treasure trove of products – from the freshest produce to the most delicate pharmaceuticals. Within these temperature-controlled havens, PT. Bangkit Jaya Teknik Indonesia fine-tunes the environment, ensuring that every item retains its pristine state. Through meticulous management, cutting-edge technology, and an unwavering commitment to excellence, they set a new standard for refrigerated warehousing.

The complexity of refrigerated warehouse services goes beyond simple temperature regulation. With the mastery of PT. Bangkit Jaya Teknik Indonesia, it encompasses a delicate equilibrium of humidity, air circulation, and precise monitoring. Each aspect is calibrated with meticulous attention to detail, resulting in a preservation nirvana where products bask in the perfect conditions.

Customization is a hallmark of PT. Bangkit Jaya Teknik Indonesia's approach. They understand that each product has unique needs, and no two industries are alike. Thus, their refrigerated warehouse services are tailored to fit, with solutions that accommodate a variety of storage requirements – from short-term storage to long-term preservation.

Beyond the technological marvel lies a dedication to partnership. PT. Bangkit Jaya Teknik Indonesia collaborates closely with clients, ensuring that their unique needs are met. Whether it's seamless integration into existing supply chains or the development of strategic storage plans, their team is a steadfast ally in the journey towards excellence.

The impact of PT. Bangkit Jaya Teknik Indonesia's refrigerated warehouse services extends far beyond the warehouse walls. They are enablers of safe food consumption, guardians of pharmaceutical efficacy, and linchpins in the global supply chain. Each package that arrives intact at the consumer's doorstep is a testament to the dedication and precision invested by the company.

In a world where freshness is valued and safety is paramount, PT. Bangkit Jaya Teknik Indonesia's refrigerated warehouse services are a beacon of reliability. They ensure that the quality promised by manufacturers reaches consumers, unmarred and unblemished. This is not just warehousing; this is a commitment to quality assurance, a testament to their legacy as pioneers of preservation.

As industries evolve and consumer demands intensify, PT. Bangkit Jaya Teknik Indonesia remains at the forefront of refrigerated warehouse services, championing the preservation of perfection. Through their expertise, every product that enters their domain embarks on a journey of excellence – a journey that promises freshness, quality, and the unwavering pursuit of perfection.

Unlocking the Chilly World of Cold Storage: Where Preservation Meets Innovation

In the realm of preserving the essence of freshness, there exists a silent hero - Cold Storage. These are specialized spaces, meticulously designed to maintain precise temperature conditions, housing an array of perishable products. The sole purpose? To keep these treasures as crisp as the day they were born.

Today, the allure of cold storage transcends boundaries, attracting industries far and wide. From pharmaceuticals and food processing to fisheries, retail, restaurant chains, meat importers, agricultural markets, and beyond. It's not just a haven for the owners; they often extend their icy embrace to others in need.

Cold storage comes in various forms, each with its unique purpose. Let's delve into the chill!

1. Chilled Room and Freezer Room

Chilled rooms and freezer rooms are the backbone of cold storage. They maintain specific temperature conditions, ensuring products remain in pristine condition. Chilled rooms hover between 1°C to 7°C, preserving the freshness of fruits, vegetables, and other delicacies for a fleeting 60 days.

Thawing rooms can double as chilled rooms, with a temperature setting of 10°C. Ideal for elevating the temperature of fresh raw materials before cooking. Freezer rooms, on the other hand, plunge to -15°C to -20°C, a frosty abode for meats, dairy, and other freeze-hungry items.

2. Blast Freezer and Blast Chiller

When it's all about swift cooling, blast freezers and blast chillers swoop in. These rapid-cooling wonders maintain temperatures between 1°C to 4°C and are the unsung heroes behind post-cooking temperature plunge. They turn piping hot creations into chilled delights in no time. Blast freezers go the extra mile, reaching temperatures as low as -20°C to -35°C, ensuring the preservation of frozen and processed foods.

Beyond the icy embrace, these marvels serve a higher purpose - safeguarding against bacterial contamination, preserving the flavors, reducing moisture, and retaining nutritional value. A symphony of science dedicated to culinary perfection.

However, the heart of every cold storage beats to the rhythm of temperature stability. Maintaining the ideal temperature is paramount. A fluctuation in room temperature can spell disaster, not only for the stored goods but for the cooling systems themselves. The challenge lies in the ebb and flow of goods entering and leaving the cold storage. Each opening of the warehouse door allows the external heat to seep in, disrupting the delicate balance.

Enter the savior - the loading system. The latest innovation, the stepped dock system, ensures that vehicles or trucks can open their doors within the confines of the warehouse. No more gaps, no more temperature turmoil during loading and unloading.

Beyond temperature stability, several other factors demand attention in cold storage management:

1. Clean & Calibrate:

The cooling machinery within the warehouse must remain pristine, subject to strict maintenance controls.

2. Know Your Hot and Cold Areas:

In a vast storage facility with varying temperature zones, meticulous placement of products is essential.

3. Embrace Pre-Cooling:

Certain products benefit from pre-cooling before entering cold storage.

4. Ward Off Air Pollution and Pest Intrusions:

A vigilant watch is essential to protect the stored goods from air pollutants and unwanted guests.

5. Rigorous Product Inspection During Receiving:

The receiving process should involve rigorous product checks to ensure quality.

In the world of cold storage, precision and innovation dance hand in hand, preserving the world's freshest treasures. It's a delicate balance between science and art, a testament to human ingenuity.

Reference: "The Complete Book on Cold Storage, Cold Chain & Warehouse (with Controlled Atmosphere Storage & Rural Godowns)," NPCS Board of Consultants & Engineers, 2016.

So, as the cold storage industry continues to evolve, remember, it's not just about keeping things cold; it's about preserving perfection.