The design and adaptation of a commercial cold storage room for the Umudike community and its environs would involve several key considerations and steps to ensure effective functionality and suitability for local needs. Cold storage facilities are critical for preserving perishable goods in regions where temperature control is essential due to climatic conditions or economic activities such as agriculture or fisheries.

Key Considerations for Design and Adaptation

-

Local Climate and Environmental Conditions:

- Understanding the local climate is crucial for designing a cold storage facility. Factors such as temperature fluctuations, humidity levels, and prevailing weather patterns need to be considered. This helps in determining the required insulation levels, refrigeration capacity, and moisture control systems.

-

Targeted Use and Storage Requirements:

- Identifying the specific perishable goods to be stored (e.g., fruits, vegetables, fish, meat) and their volume helps in designing the storage capacity and layout of the cold storage room. Different products may have varying temperature and humidity requirements, necessitating segregated storage areas or adjustable climate zones within the facility.

-

Energy Efficiency and Sustainability:

- Given the potential energy-intensive nature of cold storage facilities, incorporating energy-efficient technologies and sustainable practices is essential. This includes selecting refrigeration systems with high Coefficient of Performance (COP), utilizing insulation materials with low thermal conductivity, and considering renewable energy sources where feasible.

-

Adaptation to Local Infrastructure and Resources:

- Adapting the cold storage room design to local infrastructure capabilities and availability of resources (such as electricity supply and water for cooling systems) ensures operational feasibility and reduces dependency on external factors. It may involve integrating backup power systems or alternative cooling methods to mitigate potential disruptions.

-

Compliance with Regulatory Standards:

- Ensuring compliance with local and national regulatory standards for food safety, hygiene, and environmental protection is critical. This includes requirements for insulation materials, refrigerants, waste management, and occupational health and safety practices.

Steps in Designing and Implementing the Cold Storage Room

-

Site Assessment and Planning:

- Conducting a thorough site assessment to determine the location, size, and orientation of the cold storage facility. Factors such as accessibility for deliveries and proximity to market areas or production sites are considered during this phase.

-

Architectural and Structural Design:

- Developing detailed architectural plans that incorporate optimal layout and spatial arrangement for efficient workflow and product handling. Structural integrity and durability are prioritized to withstand local environmental conditions and operational demands.

-

Mechanical and Electrical Systems Design:

- Designing the refrigeration system, ventilation, and humidity control mechanisms to maintain stable internal conditions. This includes selecting appropriate refrigerants (considering environmental impact and efficiency), sizing compressors, and integrating automated control systems for temperature monitoring and adjustment.

-

Insulation and Construction Materials:

- Choosing insulation materials that provide effective thermal resistance and moisture control, considering local availability and cost-effectiveness. Construction materials should be durable, easy to clean, and resistant to corrosion or degradation in cold and humid environments.

-

Installation and Commissioning:

- Overseeing the construction and installation process to ensure adherence to design specifications and regulatory requirements. Commissioning involves testing and adjusting systems to verify operational efficiency and reliability before full-scale use.

-

Training and Maintenance Planning:

- Providing training to staff on proper operation, maintenance, and safety procedures for the cold storage facility. Establishing a regular maintenance schedule to inspect equipment, monitor performance metrics, and address any issues promptly.

Conclusion

Designing and adapting a commercial cold storage room for the Umudike community and its environs requires a comprehensive approach that integrates technical expertise, environmental considerations, and local needs. By addressing key factors such as climate conditions, storage requirements, energy efficiency, infrastructure compatibility, and regulatory compliance, a well-planned cold storage facility can enhance food security, support economic activities, and contribute to sustainable development in the region.

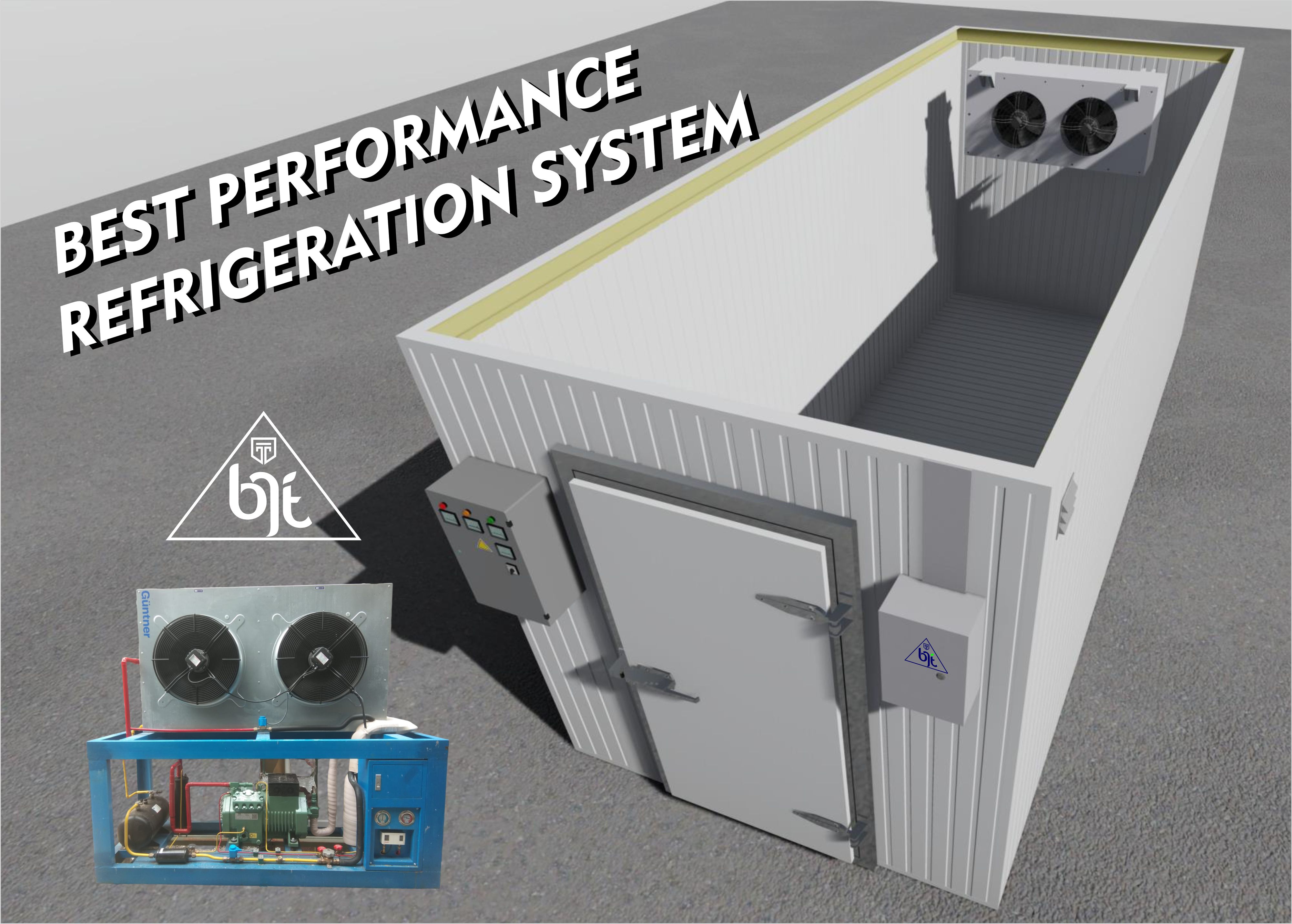

Sistem Refrigerasi Industri: Fondasi Kesuksesan Proses Industri

Sistem refrigerasi industri adalah tulang punggung dari berbagai industri yang mengandalkan pengendalian suhu untuk menjaga kualitas produk dan menjalankan proses produksi dengan efisiensi. PT. BJT INDONESIA, sebagai pemimpin dalam industri ini, telah mengambil peran penting dalam merancang dan menyediakan sistem refrigerasi industri yang andal dan efisien untuk berbagai keperluan.

Sistem Refrigerasi Industri: Mengapa Penting?

1. Makanan dan Minuman: Dalam industri makanan dan minuman, sistem refrigerasi industri diperlukan untuk menjaga produk segar dan aman. Ini termasuk penyimpanan daging, produk susu, buah-buahan, dan minuman yang semuanya memerlukan suhu yang tepat agar tetap awet dan bebas dari kerusakan mikroorganisme.

2. Farmasi: Industri farmasi memerlukan kontrol suhu yang ketat untuk mempertahankan kualitas obat-obatan dan bahan kimia. Sistem refrigerasi digunakan dalam penyimpanan bahan baku, produksi, dan penyimpanan produk jadi.

3. Petrokimia: Proses-proses di industri petrokimia sering kali memerlukan pendinginan yang ekstrem untuk menjaga peralatan tetap berfungsi dan mencegah bahaya yang dapat timbul dari suhu tinggi.

4. Elektronik: Dalam pembuatan komponen elektronik, suhu yang tepat sangat penting. Sistem refrigerasi digunakan untuk menjaga suhu dalam rentang yang diperlukan agar produksi elektronik berjalan dengan baik.

Jenis Sistem Refrigerasi Industri

PT. BJT INDONESIA menyediakan berbagai jenis sistem refrigerasi industri, termasuk:

1. Cold Room: Digunakan untuk penyimpanan bahan makanan dan produk-produk yang memerlukan suhu rendah dan stabil.

2. Freezer: Didesain khusus untuk penyimpanan makanan beku dan produk-produk lain yang memerlukan suhu sangat rendah.

3. Chiller: Digunakan untuk mendinginkan cairan atau gas dalam proses industri, seperti dalam produksi minuman dingin atau pemrosesan kimia.

4. Pendingin Udara: Penting dalam berbagai proses industri untuk menjaga suhu di dalam ruangan tetap nyaman bagi pekerja dan peralatan.

Perancangan Sistem Refrigerasi Industri

PT. BJT INDONESIA memiliki tim ahli yang berpengalaman dalam merancang sistem refrigerasi industri yang sesuai dengan kebutuhan setiap pelanggan. Perancangan sistem yang tepat sangat penting untuk menjaga efisiensi operasional, menghemat energi, dan menjaga keselamatan.

Dengan menggabungkan teknologi terkini, perencanaan yang cermat, dan komitmen terhadap kualitas, PT. BJT INDONESIA telah menjadi mitra terpercaya untuk berbagai industri dalam memenuhi kebutuhan mereka akan sistem refrigerasi industri yang kuat dan andal.

Dalam dunia yang semakin bergantung pada kontrol suhu yang ketat, sistem refrigerasi industri adalah komponen vital dalam memastikan kesuksesan dan keamanan operasi industri. PT. BJT INDONESIA memahami betul peran penting ini dan terus berinovasi dalam menyediakan solusi yang unggul untuk pelanggan-pelanggan industri di seluruh Indonesia.

Sistem refrigerasi industri umumnya menggunakan refrigeran, yaitu zat yang digunakan untuk mentransfer panas dari lingkungan pendingin ke lingkungan yang lebih panas. Refrigeran ini biasanya berupa gas atau cairan, tergantung pada jenis sistem refrigerasi yang digunakan.

Selain itu, sistem refrigerasi industri juga dapat dilengkapi dengan kontrol suhu yang canggih, yang memungkinkan pengaturan suhu yang sangat presisi dan terkendali. Hal ini sangat penting dalam industri yang membutuhkan suhu yang tepat untuk menjaga kualitas produk dan keamanannya.

Dalam industri makanan dan minuman, misalnya, sistem refrigerasi industri digunakan untuk menjaga kesegaran dan keamanan produk, menghindari pertumbuhan bakteri dan jamur, serta mempertahankan tekstur dan rasa yang diinginkan. Sedangkan dalam industri farmasi, sistem refrigerasi industri digunakan untuk menyimpan obat-obatan dan bahan kimia dengan suhu dan kelembaban yang terkontrol.

Dalam pengoperasiannya, sistem refrigerasi industri juga memerlukan perawatan dan pemeliharaan secara teratur untuk menjaga kinerjanya yang optimal. Beberapa faktor yang dapat mempengaruhi kinerja sistem refrigerasi industri antara lain suhu lingkungan, kelembaban udara, dan kondisi peralatan.

Dalam kesimpulannya, sistem refrigerasi industri adalah sistem pendingin yang digunakan dalam berbagai aplikasi industri untuk menjaga suhu yang terkendali dan optimal pada produk dan proses. Sistem ini sangat penting dalam menjaga kualitas dan keamanan produk serta efisiensi dan kinerja proses industri.

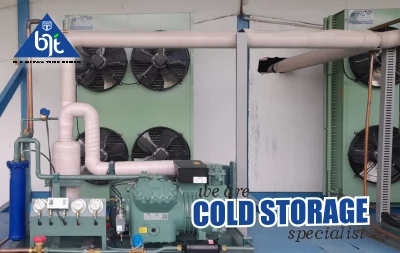

An industrial refrigeration system is a complex and critical component of many manufacturing and processing facilities. It plays an important role in ensuring that raw materials, finished products, and equipment are kept at optimal temperatures to maintain quality, prevent spoilage, and ensure the safe and efficient operation of the facility. In this article, we will explore the basics of industrial refrigeration systems, their components, and their importance in various industries.

Industrial refrigeration systems are used in a wide range of industries, including food and beverage production, chemical processing, pharmaceuticals, and HVAC. These systems are designed to control the temperature of a given space, equipment or product. They work by removing heat from the air or liquid that needs to be cooled, and then rejecting that heat outside of the building.

The components of an industrial refrigeration system typically include a compressor, condenser, evaporator, and expansion valve. The compressor is responsible for compressing the refrigerant gas and moving it through the system. The condenser then removes the heat from the compressed gas and converts it back into a liquid state. The liquid refrigerant then passes through an expansion valve, which causes it to expand and cool as it enters the evaporator. The evaporator absorbs heat from the surrounding air or liquid, which cools the desired space or product.

One of the most critical aspects of industrial refrigeration system design is selecting the appropriate refrigerant. The refrigerant is the fluid that absorbs and releases heat as it cycles through the system. Different refrigerants have different properties, such as their boiling points and environmental impact. The selection of the refrigerant depends on several factors, including the temperature range required, the size of the system, and environmental considerations.

In addition to selecting the right refrigerant, proper system maintenance is essential to ensure the longevity and optimal performance of the industrial refrigeration system. Regular maintenance should include cleaning the condenser and evaporator coils, checking for refrigerant leaks, and inspecting electrical connections and other components. Proper maintenance can help to prevent breakdowns, reduce energy consumption, and extend the life of the system.

In conclusion, industrial refrigeration systems are a vital component in many manufacturing and processing industries. They play an essential role in maintaining the quality and safety of products and equipment, as well as ensuring the efficient operation of facilities. Understanding the basic components of industrial refrigeration systems, the importance of selecting the right refrigerant, and the importance of regular maintenance is crucial for anyone working in or around these systems.