Menguasai Seni Pembekuan Cepat: Teknik, Resep, dan Praktik Terbaik

Pembekuan cepat adalah teknik penting dalam pengolahan makanan yang memungkinkan Anda mempertahankan kualitas dan kesegaran makanan. Dalam artikel ini, kita akan membahas teknik, resep, dan praktik terbaik dalam seni pembekuan cepat.

Teknik Pembekuan Cepat: Pentingnya Suhu dan Kecepatan

Proses pembekuan cepat melibatkan menurunkan suhu makanan dengan cepat hingga di bawah titik beku. Hal ini dilakukan untuk menghentikan pertumbuhan mikroorganisme dan enzim yang dapat merusak makanan. Kecepatan adalah kunci dalam teknik ini. Semakin cepat suhu makanan menurun, semakin baik kualitasnya akan terjaga.

Ada beberapa cara untuk mencapai pembekuan cepat, seperti menggunakan blast freezer atau blast chiller. Mesin-mesin ini dapat menurunkan suhu makanan dengan sangat cepat, mencegah pembentukan kristal es yang besar, dan mempertahankan tekstur dan rasa asli makanan. Teknik ini digunakan dalam industri makanan mulai dari restoran hingga produsen makanan siap saji.

Resep untuk Pembekuan Cepat

Pembekuan cepat dapat diterapkan pada berbagai jenis makanan, termasuk daging, ikan, sayuran, buah-buahan, dan makanan siap saji. Beberapa resep khusus dirancang untuk pembekuan cepat, mempertimbangkan suhu dan waktu yang dibutuhkan untuk memastikan kualitas makanan tetap terjaga.

Misalnya, dalam pembuatan makanan beku, penting untuk memilih makanan yang memiliki tekstur yang baik setelah dibekukan. Buah dan sayuran bisa dibekukan dalam bentuk potongan kecil atau puree untuk memudahkan penggunaan selanjutnya. Sementara itu, daging atau ikan bisa dibekukan dalam bentuk steak atau filet, dengan perhatian khusus terhadap pelapis untuk mencegah oksidasi dan perubahan warna.

Praktik Terbaik dalam Pembekuan Cepat

Selain menguasai teknik dan resep, ada praktik terbaik yang harus diperhatikan dalam pembekuan cepat. Ini termasuk memastikan makanan bersih dan segar sebelum dibekukan, serta menghindari overdosis suhu pada mesin pembekuan cepat. Selain itu, penting untuk memiliki catatan tentang tanggal pembekuan agar dapat memonitor umur simpan makanan yang dibekukan.

Dengan menguasai seni pembekuan cepat, Anda dapat mempertahankan kualitas makanan dan mengurangi pemborosan. Ini adalah teknik penting yang diperlukan oleh banyak pengusaha di industri makanan yang ingin menyajikan makanan berkualitas tinggi kepada pelanggan mereka.

Menguasai Seni Pembekuan Cepat: Teknik, Resep, dan Praktik Terbaik

Menguasai seni pembekuan cepat melibatkan pemahaman mendalam tentang teknik, resep, dan praktik terbaik yang diperlukan untuk menjaga kualitas makanan selama proses ini. Berikut adalah beberapa poin penting yang perlu diperhatikan dalam seni pembekuan cepat:

1. Pemahaman Tentang Blast Freezing:

- Pembekuan cepat adalah teknik pendinginan makanan dengan sangat cepat untuk mencegah pertumbuhan bakteri dan menjaga kualitas. Pemahaman yang baik tentang prinsip-prinsip di balik pembekuan cepat adalah langkah awal yang penting.

2. Suhu yang Tepat:

- Blast freezing dilakukan pada suhu yang sangat rendah, seringkali di bawah -18°C atau bahkan lebih rendah, tergantung pada jenis makanan. Suhu yang tepat penting untuk memastikan pembekuan yang efektif.

3. Kecepatan Proses:

- Pembekuan cepat harus dilakukan dengan sangat cepat. Ini dapat mencapai beberapa derajat di bawah nol dalam waktu singkat. Semakin cepat makanan membeku, semakin baik kualitasnya akan terjaga.

4. Kemasan yang Tepat:

- Makanan yang akan dibekukan harus dikemas dengan benar. Penggunaan kemasan yang tahan terhadap suhu rendah dan vakum dapat membantu melindungi makanan dari pembekuan yang tidak merata atau kerusakan oleh pembekuan.

5. Resep dan Jenis Makanan:

- Tidak semua makanan cocok untuk pembekuan cepat. Beberapa makanan, seperti daging, ikan, atau makanan cairan, lebih sesuai daripada yang lain. Resep dan jenis makanan harus dipertimbangkan dengan cermat.

6. Praktik Terbaik:

- Mengikuti praktik terbaik dalam pemilihan makanan, pengemasan, pengaturan suhu, dan durasi pembekuan sangat penting. Ini dapat mencakup menghindari overpacking freezer untuk memastikan sirkulasi udara yang baik.

7. Penggunaan Hasil Blast Freezing:

- Makanan yang dibekukan dengan baik dapat digunakan dalam berbagai resep, termasuk makanan beku, sup, hidangan panggang, dan banyak lagi. Pengetahuan tentang cara mengolah makanan yang dibekukan adalah kunci dalam seni ini.

Kesimpulan : Menguasai seni pembekuan cepat, atau blast freezing, adalah aspek penting dalam industri makanan. Dengan pemahaman mendalam tentang teknik, penggunaan suhu yang tepat, dan praktik terbaik, kita dapat menjaga kualitas makanan, memperpanjang umur simpan produk, dan memastikan keamanan konsumen. Penggunaan blast freezing memungkinkan bisnis makanan untuk menyajikan makanan berkualitas tinggi sepanjang tahun, mengurangi pemborosan, dan memberikan fleksibilitas dalam persiapan hidangan. Oleh karena itu, memahami seluk-beluk blast freezing adalah langkah penting dalam menghadapi tuntutan makanan yang tinggi dalam industri modern.

Dalam pembekuan cepat, kunci utamanya adalah menjaga suhu yang sangat rendah dan meningkatkan kecepatan proses. Hal ini memungkinkan kita untuk menjaga makanan tetap segar, menghentikan pertumbuhan bakteri, dan menjaga tekstur serta rasa yang optimal. Penggunaan kemasan yang sesuai dan pengetahuan tentang jenis makanan yang cocok untuk blast freezing juga sangat penting. Seiring dengan perancangan resep yang tepat, blast freezing membuka pintu bagi penggunaan kreatif makanan yang dibekukan dalam berbagai hidangan yang berkualitas tinggi. Dengan kata lain, seni blast freezing tidak hanya memungkinkan kita untuk mempertahankan kualitas makanan, tetapi juga menghadirkan kemungkinan tak terbatas dalam pengolahan dan penyajian makanan yang lezat.

Dalam dunia industri pemprosesan makanan, pembekuan berdenyut merupakan pencerobohan yang mengagumkan. Ia membawa peluang untuk meningkatkan produktiviti, kualiti produk, dan hasil. Namun, keselamatan tidak boleh diabaikan dalam usaha untuk mencapai hasil yang cemerlang. Dengan mengamalkan langkah-langkah keselamatan dan terus memprioritaskan kebajikan pekerja dan prestasi peralatan, kita mencipta keseimbangan yang sempurna antara kecekapan dan kasih sayang.

Maka, marilah kita terus melangkah ke hadapan dengan tekad, bukan sahaja untuk mencapai prestasi luar biasa dalam industri, tetapi juga untuk memastikan bahawa perjalanan kita ke arah keunggulan sentiasa dilalui dengan keselamatan dan kepedulian. Ini adalah titik permulaan untuk transformasi yang menakjubkan dan kejayaan yang abadi.

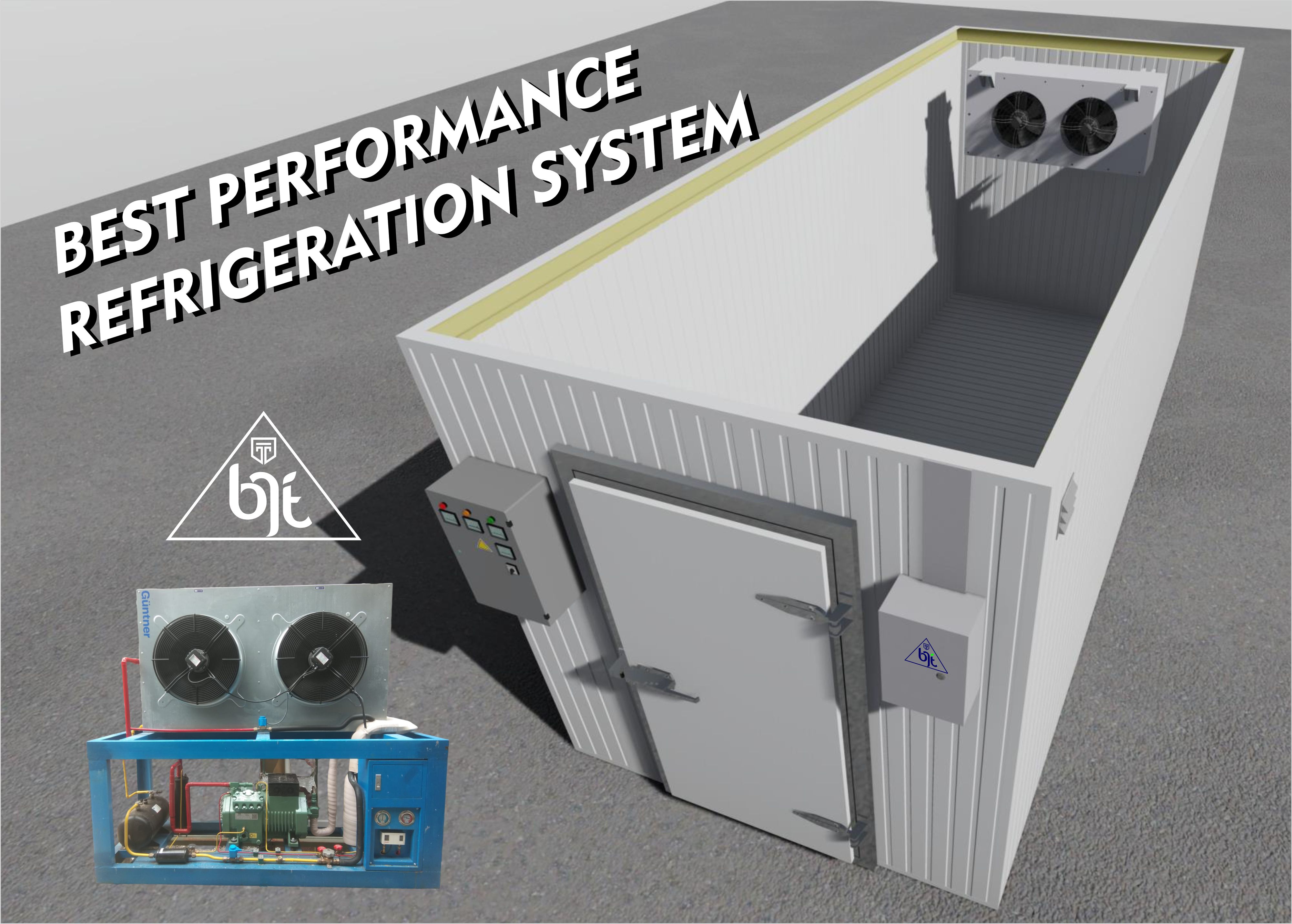

PT. BJT Indonesia adalah perusahaan yang mengkhususkan diri dalam penjualan Blast Freezer Room di Indonesia. Mereka menawarkan berbagai kapasitas, mulai dari 2 ton hingga 200 ton. Blast Freezer Room adalah perangkat yang penting dalam industri makanan dan banyak bisnis lainnya, yang memungkinkan proses pembekuan cepat untuk menjaga kualitas dan keamanan makanan. Dengan rentang kapasitas yang luas ini, PT. BJT Indonesia dapat memenuhi kebutuhan berbagai jenis bisnis dan industri di seluruh Indonesia, membantu mereka mempertahankan produk makanan dalam kondisi optimal dan memenuhi standar ketat dalam penyajian makanan yang berkualitas.

Mastering the Art of Blast Freezing: Techniques, Recipes, and Best Practices

Introduction to Blast Freezing: What is it, Why is it Important, and How it Works

Blast freezing is a method of rapidly freezing food products to preserve their quality and freshness. It is widely used in the food industry, from restaurants and catering businesses to large-scale food manufacturing facilities. However, the benefits of blast freezing can also be enjoyed by home cooks and small-scale food producers.

Mastering the Art of Blast Freezing is a comprehensive guide to this essential food preservation technique. Whether you are a professional chef looking to streamline your kitchen operations or a home cook who wants to preserve the bounty of the harvest, this book has everything you need to know.

In this book, you will learn the basics of blast freezing, including how it works and why it is important. You will discover the different types of blast freezers available and learn how to choose the right one for your needs. You will also find safety precautions and best practices for operating a blast freezer, as well as step-by-step instructions for setting one up.

But this book is not just about the technical aspects of blast freezing. You will also find a wealth of information on how to prepare foods for blast freezing, from raw ingredients to cooked meals and baked goods. You will learn about the best packaging techniques to ensure your food stays fresh and flavorful, and discover which types of foods benefit most from blast freezing.

Whether you are a professional chef or a home cook, this book is an invaluable resource for anyone looking to master the art of blast freezing. With detailed instructions, expert tips, and mouthwatering recipes, you will be able to freeze food like a pro and enjoy the benefits of blast freezing for years to come.

Introduction to Blast Freezing: What is it, Why is it Important, and How it Works

Blast freezing is a method of freezing food products quickly and efficiently. Unlike traditional freezing methods, which can take hours or even days, blast freezing can freeze food in a matter of minutes. This rapid freezing process has many benefits, including better preservation of flavor, texture, and nutrients.

In this chapter, we will explore the basics of blast freezing, including how it works and why it is important. We will also discuss the advantages of blast freezing over other methods of food preservation.

How Blast Freezing Works

Blast freezers work by circulating cold air over food products at high speeds. This rapid movement of cold air removes the heat from the food quickly, causing it to freeze rapidly. The temperature of the blast freezer is typically set at -40°C or lower, which ensures that the food freezes as quickly as possible.

The high-speed airflow also helps to prevent ice crystals from forming on the food. Ice crystals can damage the texture and quality of food, which is why blast freezing is preferred over slower freezing methods.

Why Blast Freezing is Important

Blast freezing is important for several reasons. First and foremost, it helps to preserve the quality of food products. Rapid freezing ensures that the food retains its flavor, texture, and nutrients. This is especially important for delicate foods like seafood and vegetables, which can lose their quality quickly if not preserved properly.

Blast freezing also helps to reduce the risk of foodborne illness. By freezing food products quickly, the growth of harmful bacteria and other pathogens is slowed or stopped. This is especially important for raw meats, which can carry harmful bacteria like Salmonella and E. coli.

Another advantage of blast freezing is that it allows for more efficient use of storage space. Because food products are frozen quickly, they can be stacked and stored more efficiently than with slower freezing methods. This is particularly important for large-scale food production facilities, where storage space is at a premium.

Advantages of Blast Freezing Over Other Methods

While there are several methods of food preservation, blast freezing has several advantages over other methods. For example, traditional freezing methods like home freezers can take hours or even days to freeze food products. This slow freezing process can cause ice crystals to form, which can damage the texture and quality of the food.

Blast freezing also allows for more efficient use of storage space. Because food products are frozen quickly, they can be stacked and stored more efficiently than with slower freezing methods.

In addition, blast freezing can help to reduce food waste. By preserving the quality of food products, blast freezing can extend their shelf life and reduce the amount of food that is thrown away due to spoilage.

Blast freezing is an essential method of food preservation for anyone who wants to preserve the quality and freshness of their food products. Whether you are a professional chef or a home cook, blast freezing can help you to extend the shelf life of your food products and reduce the risk of foodborne illness. In the next chapter, we will explore the different types of blast freezers available and help you to choose the right one for your needs.

Type of Blast Freezer :

When it comes to blast freezers, there are several different types available on the market. Each type has its own set of advantages and disadvantages, depending on your specific needs and requirements. In this chapter, we will explore the different types of blast freezers available and help you to choose the right one for your needs.

a. Tunnel Freezers

Tunnel freezers are one of the most popular types of blast freezers on the market. They are designed to freeze large quantities of food products quickly and efficiently. Tunnel freezers work by passing food products through a series of conveyor belts and high-speed fans that circulate cold air over the products. The cold air freezes the products quickly, allowing for high-volume production. Tunnel freezers are ideal for large-scale food production facilities, such as food processing plants and commercial kitchens. They can freeze large quantities of food products quickly, which helps to reduce production times and increase efficiency.

b. Spiral Freezers

Spiral freezers are another popular type of blast freezer. They are similar in design to tunnel freezers, but they use a spiral conveyor belt instead of a straight one. The spiral design allows for a smaller footprint and more efficient use of space. Spiral freezers are ideal for smaller production facilities or for those with limited space.

c. Blast Chillers

Blast chillers are a type of blast freezer that are designed specifically for chilling cooked or partially cooked food products. They work by circulating cold air over the products, which rapidly cools them down to a safe temperature. Blast chillers are ideal for use in commercial kitchens, where cooked food products need to be chilled quickly to prevent the growth of harmful bacteria.

d. Batch Freezers

Batch freezers are a type of blast freezer that are designed for smaller-scale production. They are typically used by artisanal ice cream makers and other specialty food producers. Batch freezers work by freezing a small batch of food products at a time, which allows for more precise control over the freezing process.

e. Portable Blast Freezers

Portable blast freezers are a newer type of blast freezer that are designed for use in remote locations or for temporary storage. They are self-contained units that can be moved from location to location, which makes them ideal for use at outdoor events or in disaster relief situations.

Safety Precautions and Best Practices for Blast Freezing:

When choosing a blast freezer, it is important to consider your specific needs and requirements. Each type of blast freezer has its own set of advantages and disadvantages, and the right one for you will depend on factors such as the size of your production facility, the type of food products you are freezing, and your available storage space. By understanding the different types of blast freezers available, you can make an informed decision and choose the right one for your needs.

Blast freezers are powerful machines that are used to rapidly freeze food products, but they also come with potential hazards. Proper safety precautions and best practices should be followed to ensure that operators are protected from harm and that the equipment operates efficiently. In this chapter, we will explore some of the key safety precautions and best practices for blast freezing.

Personal Protective Equipment

Personal protective equipment (PPE) is essential for operators working with blast freezers. This includes gloves, safety goggles, and protective clothing. Gloves should be made of materials that provide adequate grip and insulation against the cold temperatures. Safety goggles are necessary to protect the eyes from flying debris, while protective clothing should cover the entire body to prevent exposure to cold temperatures.

Training and Supervision

Operators should be properly trained in the operation of blast freezers before being allowed to operate the equipment. Training should include instruction on the safe use of the equipment, as well as the potential hazards and how to prevent them. Operators should also be supervised to ensure that they are following proper safety protocols.

Maintenance and Inspection

Regular maintenance and inspection of the blast freezer equipment is critical to ensure that it is functioning properly and safely. This includes checking for loose or worn parts, monitoring temperature and pressure gauges, and ensuring that all safety features are working correctly.

Proper Loading and Unloading

The proper loading and unloading of the blast freezer is important to prevent injury and equipment damage. Products should be loaded onto the conveyor belts in a safe and efficient manner, without overloading the equipment. When unloading the freezer, products should be removed in a controlled manner to prevent injury or damage to the equipment.

Temperature Monitoring

Temperature monitoring is critical to ensure that the blast freezer is operating at the correct temperature. Operators should regularly monitor the temperature and make adjustments as needed to ensure that the equipment is functioning correctly. Temperature logs should be kept to track the performance of the freezer over time.

Emergency Procedures

In the event of an emergency, such as a power outage or equipment failure, operators should be trained on the proper emergency procedures. This may include shutting down the equipment or evacuating the area. Emergency procedures should be clearly posted and reviewed regularly to ensure that all operators are aware of what to do in an emergency situation.

Conclusion

Blast freezing is a powerful technology that can help to increase efficiency and reduce production times in food processing facilities. However, it is important to follow proper safety precautions and best practices to ensure that operators are protected from harm and that the equipment operates efficiently. By following these guidelines, you can ensure that your blast freezer is operating safely and effectively.